The material characteristics are different depending on the rolling direction; The material does not react in the same way if the part is bent in the grain direction, or perpendicularly; Some materials like aluminium are more sensitive too, while others are less, stainless steel for example.

The fact that the material fiber is more rigid in one direction than the other should also be taken into account:

- When a part is bent in the opposite direction to the rolling, the bending resistance is stronger. The pressure needed to hold the angle will be greater, due to powerful spring back.

- On the other hand, when bending is carried out in the direction of the grain, the material will be easier to "break", because of less spring back and more even bending.

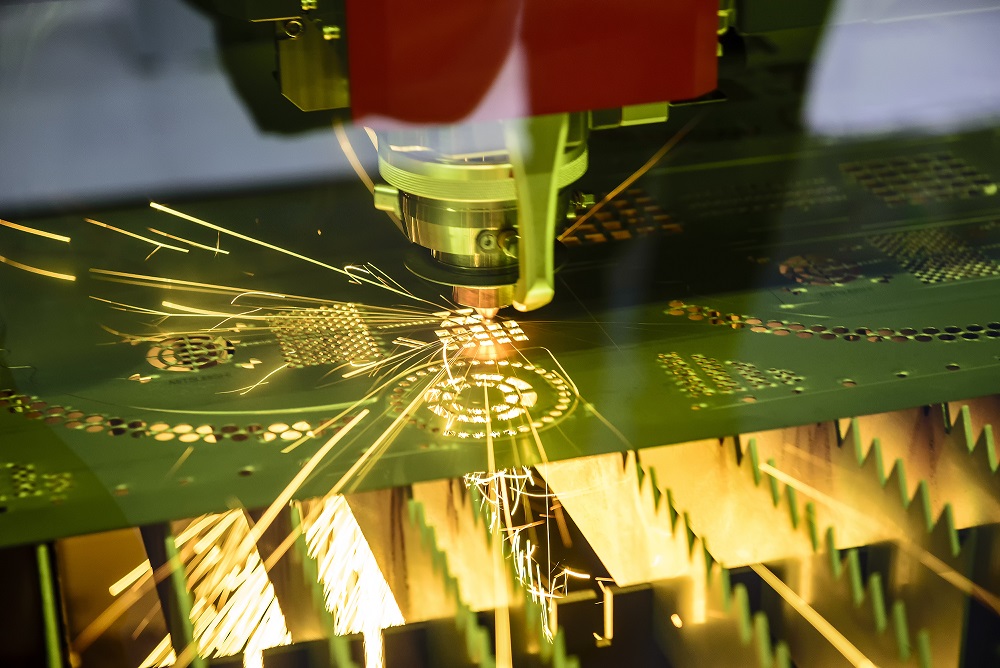

Photo : copyright AIMM compagny

One solution: bending the parts 45° to the fiber direction

To optimize the constraints and benefits of the rolling direction, manufacturers producing high demanding parts, such as in aeronautics, cut parts at a "45°" angle. However, this "45°" bending operation often comes at the expense of the offcut rate, because nesting during cutting is less optimal.

To optimize the constraints and benefits of the rolling direction, manufacturers producing high demanding parts, such as in aeronautics, cut parts at a "45°" angle. However, this "45°" bending operation often comes at the expense of the offcut rate, because nesting during cutting is less optimal.

Cutting a part "at 45° to the rolling direction" means that the fiber is positioned 45° to the structural lines, which allows solid resistance over the entire length of the structural lines. The repeatability and mechanical strength of the piart are better.Pierrick Grand - Extratole explains "when producing parts for the aeronautics sector, we systematically cut the pieces at 45 degrees to the grain to meet the precision constraints of this sector.

In the majority of other cases, we prefer to optimize the material by nesting without limiting the rotation direction of the parts." 45° positioning also provides evenness in terms of the bending angle, which allows to maintain a single setting for all identical bends. In comparison, as when folding a box that has been cut "at 90° to the grain direction", a double adjustment will be necessary: the first to bend the 2 structural lines in the grain direction, then a second for the 2 bends in the other direction.

45° positioning also provides evenness in terms of the bending angle, which allows to maintain a single setting for all identical bends. In comparison, as when folding a box that has been cut "at 90° to the grain direction", a double adjustment will be necessary: the first to bend the 2 structural lines in the grain direction, then a second for the 2 bends in the other direction.

Gerrit Gerritsen - Bystronic adds "limiting the problem of the direction of rolling and spring back requires a punch radius that is at least the same thickness of the steel sheet. The result is less waste, less scrap, therefore more correct parts."

Bending is prepared beforehand as early as the cut

Copyright Bystronic Preparing for bending beforehand, when the parts are being cut, is an important element.

In the case of a 45° positioning, the company's objective will be to constrain the nesting in order to obtain the level of resistance and the most optimum constancy during bending.

Whereas, when the choice is to optimize the material, the company will nest the parts without taking the rolling direction into account.Clément Contet - Arcode, explains that "In this scenario, the bending operator must examine the laser or punch nesting software to determine how the parts were cut. If there are parts in both directions of rolling, the operator needs to inspect in order to be in line in terms of tolerance."

It is important to pay particular attention when sorting the parts at the cutting machine output. By sorting the parts into stacks according to the direction of rolling, the bending operator will limit the risk of error or waste, and the press brake will gain in cycle time as the operator will spend less preparation time.

Copyright - reproduction prohibited without written permission from Metal-Interface

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Bending dossier Technical article

Bending dossier Technical articleBending and material fiber: how to limit the precision impact of the bent parts?