Bystronic makes a strong impression with the launch of the ByTube Star 330, its latest 3D fiber laser tube cutting machine. Designed to maximize productivity and flexibility, it stands out as the most versatile solution on the market for the automatic machining of tubes and open sections across a diameter range from 19 to 305 mm — without requiring equipment changes.

Bystronic makes a strong impression with the launch of the ByTube Star 330, its latest 3D fiber laser tube cutting machine. Designed to maximize productivity and flexibility, it stands out as the most versatile solution on the market for the automatic machining of tubes and open sections across a diameter range from 19 to 305 mm — without requiring equipment changes.Extreme Versatility and Full Automation

Manufactured in Niederönz (Switzerland) and Cazzago San Martino (Italy), the ByTube Star 330 is redefining tube machining standards. It can process a wide variety of hollow metal tubes, commonly used in industries such as furniture manufacturing, sports equipment, and construction materials.

With a modular design and three combinable loading options, it adapts to any space constraints and can evolve with future needs. Full automation capabilities — loading, sorting, drilling, threading, marking, and bevel cutting — optimize costs and significantly accelerate production cycles.

Top Performance

Equipped with a 6 kW or 10 kW laser source, the ByTube Star 330 delivers enough power to cut even the largest and thickest tubes and profiles quickly and precisely. It is particularly efficient for parts over 250 mm in diameter and 40 kg/m, boasting the highest processing speed in its category.

Its machining capacity covers a wide range of standard profiles (C, L, H, I, U) and sizes from 19.05 x 19.05 mm up to 260 x 260 mm.

Innovation and Ease of Use

Among its many innovations, the ByTube Star 330 offers options such as Laserscan, Weld Search Camera, and Quick Cut, ensuring maximum quality, safety, and execution speed. The 3D cutting head combined with Quick Cut guarantees outstanding cutting quality even for very small tubes.

Thanks to its intuitive touchscreen and proven Bystronic HMI, using the ByTube Star 330 is as easy and fluid as using a smartphone, making advanced technology accessible without requiring technical expertise.

Impressive Dimensions for Ambitious Projects

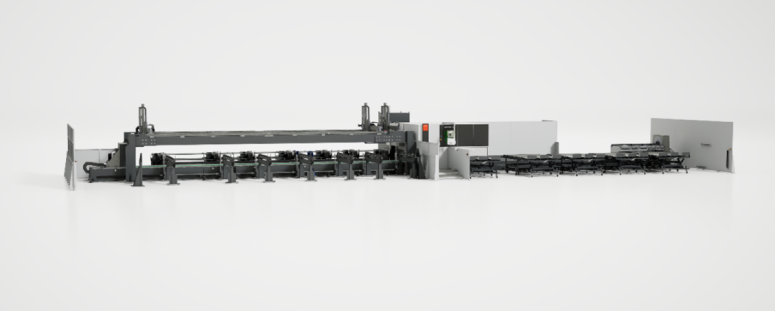

In its largest configuration, the ByTube Star 330 exceeds 32 meters in length and weighs around 40 tons. It can handle tubes up to 12.8 meters long, meeting the most demanding requirements.

In its largest configuration, the ByTube Star 330 exceeds 32 meters in length and weighs around 40 tons. It can handle tubes up to 12.8 meters long, meeting the most demanding requirements.A Revolution in Laser Tube Cutting

"The ByTube Star 330 is setting new standards in laser tube cutting," says Dr. Daniel Brenner, Global Head Marketing & Sales Tube at Bystronic. "Thanks to its exceptional flexibility, high power, and full automation, our customers can achieve unprecedented levels of production efficiency and quality. Its modular design ensures each installation is perfectly tailored to specific needs, making it a true technological breakthrough, especially for complex parts."

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

2D Laser cutting Press release

2D Laser cutting Press releaseByTube Star 330: The New Benchmark for 3D Laser Tube Cutting

Published on 17/04/25