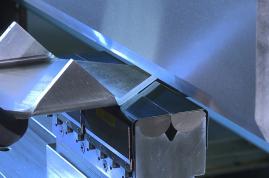

Crowning is a distortion of the ram and the bed, induced during the bending operation by the force of the table. If this deformation is not compensated, the bending angle is irregular. The majority of press brakes are equipped with a crowning system.

Clément Contet - Arcode shows his experience as a subcontractor. "Factors like material, length and tolerance are important elements in bending and involve the use of a crowning system. We produce 6 meter parts, and without crowning the bend becomes completely wrong! The distortion is consequently substantial. »

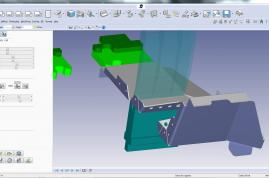

Copyright Bystronic Gerrit Gerritsen - Bystronic explains that "to counteract and compensate the deformation of the press brake, it is essential to have:

- Several hydraulic cylinders along the length and mid-height of the lower beam, to guarantee perfect compensation of the flexing of the machine caused by the bending of the part.

- The amount of compensation and the exact position of this deformation must be measured with pressure sensors independently in the cylinders. All this must be done in real time during bending.

- "Dynamic crowning" must allow for perfect parallelism between the upper and lower beams, and as a result in a constant angle over the entire length of the bend.

- Other deformations, such as deflection of the side bars or temperature change, must lead to a direct correction of the bottom dead centre. »

Finally, there is another solution for Mauricio Gutierrez Matta - SafanDarley: "We have invented and patented a pulley and belt system that prevents bending in 99% of situations for our high-precision, 100% electric press brakes. The force is distributed evenly all along the sheet to be bent. The removal of crowning allows for improvement in the precision of the bent parts. »

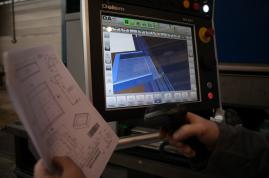

Inspection by the bending operator

Copyright AIMM For the operator, making a 3-point control of the bent should be part of habit to detect crowning problems.

And Daniel Corbion - CDMO advises to "work in the centre of the press brake to avoid "slanting" the machine. »

Gaëtan Benoit - AIMM shares his experience as a subcontractor. "During the production of the first part, we inspect all the bends and angles, as well as the functional dimensions. It is the adjuster- bender who is in control and who validates the part before starting production. »

Angle correctors on press brakes

Angle correctors also provide the bender with help, which indicates the right, left and centre dimensions and the press brake makes corrections automatically. Specifically, after the first part, the press brake operator takes the dimensions and indicates, for example, that 1 ° is missing on the left, the right is correct and the middle is missing 1.5 °, this so that the machine faces the necessary correction.

Copyright Colly-Bombled François DEBACKER - LVD states: "Many angle controllers perform the operation in two steps: the measurement of the angle, and then the correction. Our control system makes the correction at the same time, using a database geared to the bent materials, without increasing the bending time. »

Serge Bourdier - Salvagnini adds that "the angle controller is sometimes restrictive because it requires having dies of the same height. If the controller has a reading range of more than 50mm, this makes it possible to have dies of different sizes, such as a 70 mm die and one of 100 mm for example. "

Finally in conclusion, an angle controller can be of interest, but still has application limitations. A bend that isn’t released from the die cannot be measured for example.

Copyright - reproduction prohibited without written permission from Metal-Interface

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Bending dossier Technical article

Bending dossier Technical articleCrowning and inspection of bent parts