About the company

We are one of the market and technology leaders in machine tools and lasers for industrial production and our innovations impact almost every industry. Our software solutions pave the way to smart manufacturing and we enable high-tech processes in industrial electronics.

History

TRUMPF was founded in 1923 and began its corporate history as a mechanical workshop. Over the decades, the company has developed into a global leader in machine tools, lasers and electronics for industrial applications. One hundred years of innovation have driven this high-tech company through important developments, from simple sheet metal processing to the rise of CNC control and the fusion of old and new technology.

Philosophy and values

Our company is built on three fundamental pillars:

- Innovation: We are constantly looking for better ways to anticipate the needs of tomorrow

- Integrity: As a family business, we recognise the value of trust and we strive to earn our customers' and partners' trust

- Responsibility: We are committed to acting responsibly towards our customers and employees, as well as society as a whole.

These fundamental principles guide our actions and decisions, placing our customers, employees, stakeholders and society at the heart of everything we do. We strive to meet their expectations by staying true to our roots and looking to the future.

Figures

- Turnover (2022/23): €5,364.5 million.

- Incoming orders: €5,088 million.

- R&D ratio: 8.9%.

- Earnings before taxes: €615.4 million.

- Number of employees: 18,352 (as at 30 June 2022)

A complete range for every application and every type of sheet metal

- Optimised application-based solutions

- A complete offer: machines, software and services

Laser source difference

- Solid-state laser

Faster for thin sheet metal due to its wavelength

- CO2 laser

Robust laser with good cutting edges, often without the need for post-processing

Range of 2D laser cutting devices

- TruLaser Serie 1000

- Compact

- Low investment and operating costs

- TruLaser Serie 3000

- Versatile

- Flexible and reliable

- TruLaser Serie 5000

- High productivity and cost-efficiency

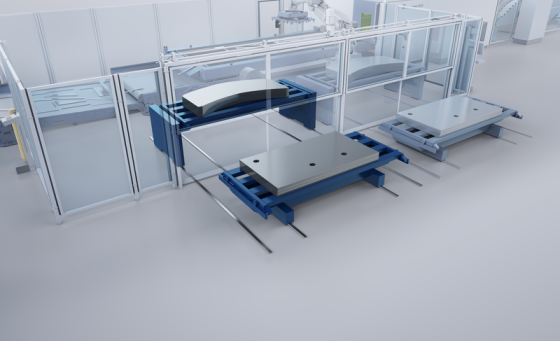

- TruLaser Center 7030

- The first fully automatic laser machine

- Integrates all processes: from design to sorted parts

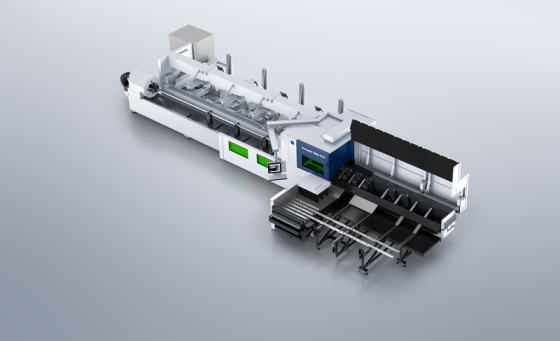

- TruLaser 8000 Coil Edition

- Cost-effective production of small to large batches

- Saves time, materials and costs

Innovative functions

- Highspeed Eco

Double your part throughput and reduce consumption

- Laser blanking

Tool-free laser cutting for various industries

- Support Bar Cleaner

Quick cleaning of bars for longer use

Ideal for 2D and 3D components, profiles and pipes

- Complete machines and systems

Range of 3D laser cutting devices

- TruLaser Cell 3000

- 2D/3D cutting, laser welding, build-up welding

- Versatility for prototypes and mass production

- TruLaser Cell 5030

- 2D and 3D laser cutting

- Suitable for small to medium batch sizes and frequent component changes

- TruLaser Cell 5030 Hotforming Edition

- 3D laser cutting system for hot-formed parts

- TruLaser Cell 7040

- Cutting, welding, build-up welding

- Suitable for the car manufacturing industry, for example

- TruLaser Cell 8030

- 3D cutting for hot-formed parts

- High productivity

- New design options with laser-cut tubes

- Savings and an improved range of parts

TruLaser Tube 3000 fiber

- Cost-effective, even if not fully utilised

- Ideal for beginners

TruLaser Tube 5000 fiber

- Fast and versatile

TruLaser Tube 7000 fiber

- Maximum productivity for tubes, including oversized ones

TRUMPF systems offer unrivalled precision in metal welding, enabling the assembly of a wide range of materials. They facilitate the transition to automated welding and exceed the quality of traditional manual welding.

Laser welding

- Provides ultimate precision and produces virtually distortion-free parts and aesthetically flawless weld seams.

MIG/MAG welding

- Uses a special power source for precise, high-quality results. Introduces a new pulsed arc welding process.

Robot-controlled welding cells

- A response to welding challenges such as a shortage of skilled labour and ever-higher quality requirements.

TRUMPF offers a wide range of marking lasers in an array of power classes and with all common wavelengths (infrared, green, ultraviolet). They are suitable for marking processes such as engraving, ablation, annealing, discolouration or foaming. TRUMPF's marking lasers process metal as well as other materials, such as plastics, glass, silicon, ceramics and organic substances.

TruMark Station 3000

- A compact and easy-to-operate solution, ideal for small to medium batches

TruMark Station 5000

- The TruMark Station 5000 can be combined with all TRUMPF marking lasers and integrated into a flow production line

TruMark Station 7000

With its large internal dimensions, the TruMark Station 7000 marking system offers plenty of space for almost any application. It doesn't matter whether the user is laser marking large individual parts weighing up to 75 kg or a particularly large number of small parts arranged side by side.

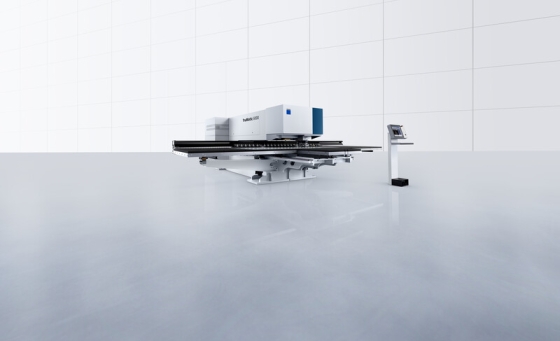

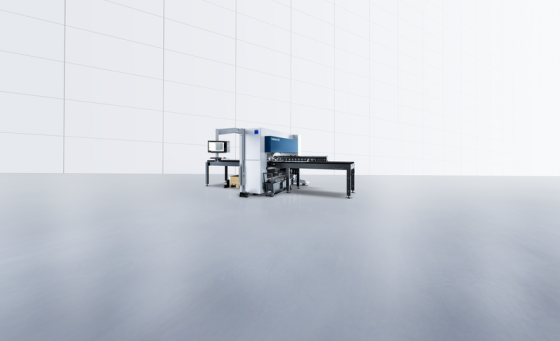

TruMatic 1000 fiber

- A compact laser machine developed for punching, bending and thread cutting

TruMatic 3000 fiber

- A productive punch laser machine that provides outstanding quality

TruMatic 5000

- A highly productive punch laser production cell

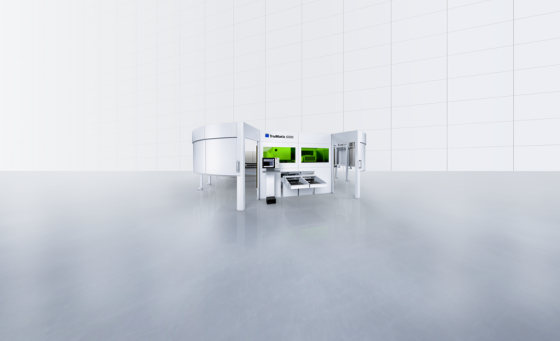

TruMatic 6000 & 6000 fiber

- Versatile, high-performing machines with a wide range of machining options

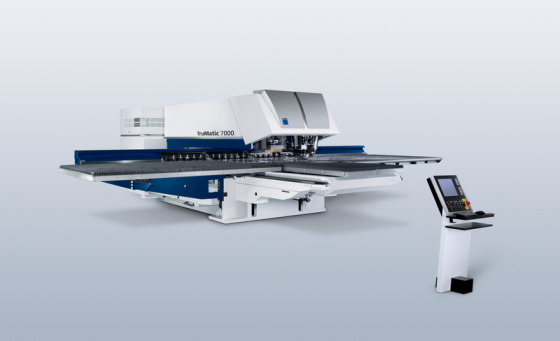

TruMatic 7000

- A high-end punch laser machine for the most demanding tasks

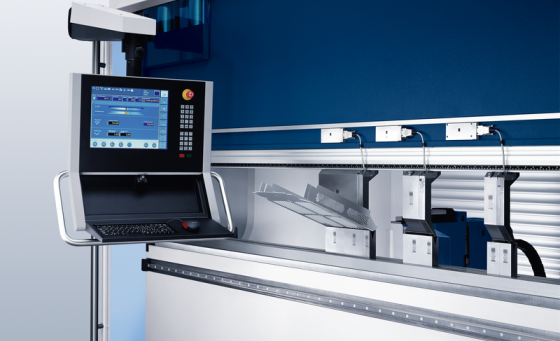

Excellence in bending

TRUMPF bending machines combine a wealth of experience with innovation, and are suitable for a wide range of applications, with manual to fully automatic solutions. They are easy to use and operate, boasting exceptional precision and optimal efficiency.

Bending machine range

- TruLaser Series 1000

- A focus on simplicity and precision

- TruBend Series 3000

- Combining TRUMPF quality with simple operation

- TruBend Series 5000

- A versatile machine for maximum productivity

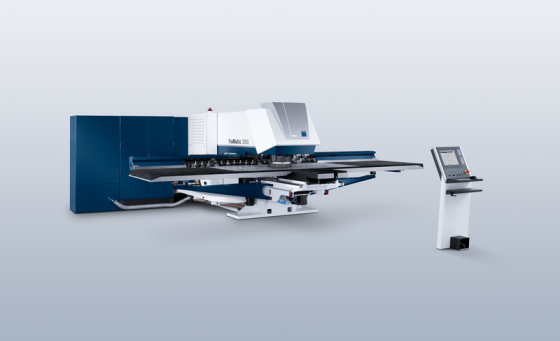

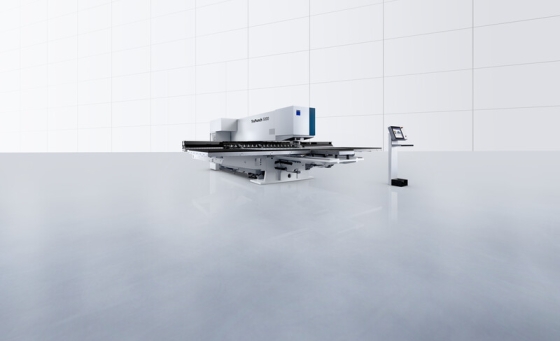

Punching

TRUMPF's TruPunch machines offer exceptional flexibility, enabling punching as well as reforming metal parts and tapping. The punching head can rotate tools at any angle, reducing set-up times and increasing productivity. Intelligent automation options facilitate the operator's work and thus maximise productivity.

TruPunch 1000

- A compact entry-level punching machine that can be automated step by step

TruPunch 3000

- Offers high productivity and combines quality with an intuitive user interface

TruPunch 5000

- Sets new standards in terms of productivity and ensures greater flexibility and precision for a wide range of parts