From CAD design to competitive advantage: How intelligent design is revolutionising manufacturing.

From CAD design to competitive advantage: How intelligent design is revolutionising manufacturing.

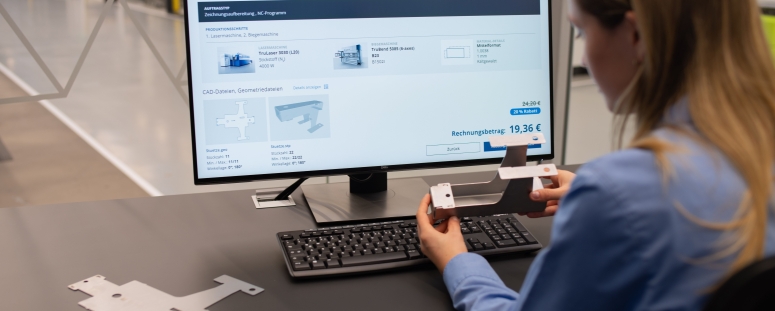

The sheet metal design of the future is far more than just a preparatory step in product development. It is a strategic lever - and with digital assistance systems, it will become an intelligent partner for designers, manufacturers and decision-makers alike.

Intelligent bending: When AI becomes a driver of innovation

Modern assistance systems automatically analyse sheet metal assemblies, identify potential for optimisation and suggest specific improvements. AI-based assistance systems enable in-depth analysis of over 60 relevant criteria such as sheet thickness, edge length or, for example, the type of connections – whether detachable or not. Design engineers can optimise the system and adapt it to their specific manufacturing processes through targeted feedback and suggestions. This feedback is fed back into the system, enabling it to continuously learn and improve. The combination of information from the design process and the evaluation of suggestions creates a dynamic learning environment that not only increases efficiency but also offers innovative solutions to complex challenges in sheet metal manufacturing.

The strength of these systems is particularly evident when it comes to bending: minimum lengths, bending radii and edge designs are checked automatically – based on real production data. The integration of simulations and the automatic evaluation of corner designs or bending collisions make these tools a real ‘quality filter’ for production.

Even beginners without in-depth prior knowledge can design production-ready assemblies after a short training period – proof of the intuitive usability and performance of the systems. In addition, the perfect symbiosis of artificial intelligence and the creative potential of designers creates innovative approaches that not only increase efficiency but also often improve product quality. This allows the industry to keep its finger on the pulse and meet the increasing demands of the market.

Data-based learning: From idea to series production

The development of such assistance systems is based on extensive data pools from real design and manufacturing projects. Intelligent evaluation and machine learning are used to create tools that not only learn from the past, but also actively contribute to improving future designs. This turns experience into a competitive advantage.

Trade fairs as laboratories of the future: Where tomorrow's visions become reality

Leading international trade fairs such as EuroBLECH are increasingly serving as experiential spaces for this transformation. In the past, leading suppliers have already demonstrated how machines, software and services can merge into a holistic ecosystem. BlechEXPO 2025 in Stuttgart is expected to focus even more strongly on AI-supported assistance systems, automated bending and data-based process optimisation.

Expected highlights of BlechExpo 2025:

- New generations of automated bending cells for small and medium batch sizes

- Advanced software solutions for tool management and simulation

- Functions for processing complex forming and deep-drawn éléments

Design as a strategic lever: the decisive advantage in global competition

Digital assistance systems not only make sheet metal design more efficient, but also more strategic: they enable early assessment of manufacturing costs, reduce waste and shorten development cycles. The integration of sustainability aspects – for example, through CO₂-optimised design proposals – has already been implemented.

Conclusion: Sheet metal design is the future – and the future remains competitive

Sheet metal design is evolving from a technical detail to a key topic in Industry 5.0. It is the approach that designers of innovation start with – and the product secures the supplier's long-term competitive advantage through the chosen manufacturing technology.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

DAO-CAO Guest columns

DAO-CAO Guest columnsRethinking sheet metal design: The key to the future of manufacturing

Published on 08/10/25