Origins and foundation

Since its creation, Bystronic has established itself as a key figure in the world of laser cutting and bending. Rooted in a spirit of constant innovation, the company has grown to offer cutting-edge solutions that meet the specific needs of its customers.

Evolution and growth

Over time, Bystronic has expanded its product portfolio, introducing new technologies and automated solutions.This growth has been the result of years of research, collaboration and understanding of the changing needs of the market.

Worldwide recognition

Bystronic's outstanding quality and commitment to excellence have earned it a worldwide reputation. Its presence in various countries testifies to its ability to meet a variety of industrial demands.

Bending and forming

Combining cutting-edge technology and expertise, Bystronic's bending solutions offer unprecedented flexibility and precision. They are designed to adapt to a variety of applications, ensuring maximum productivity.

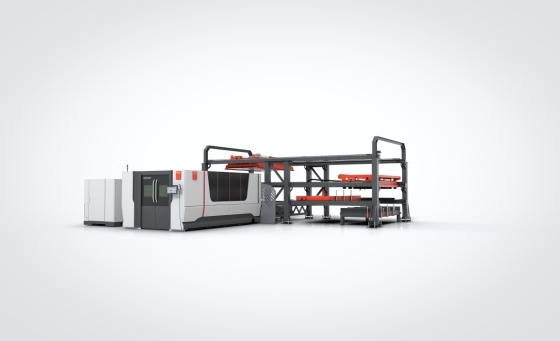

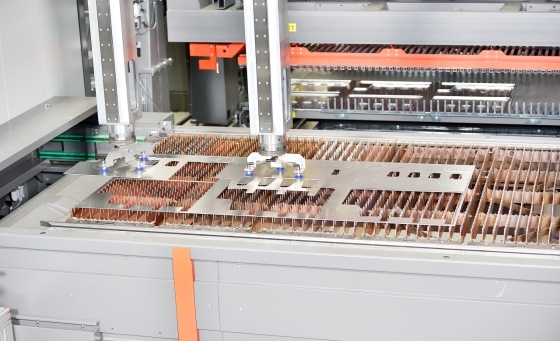

Laser cutting

At the heart of Bystronic's offering is laser cutting technology, delivering unrivalled precision and efficiency. These systems are adapted to a variety of materials, guaranteeing optimum results every time.

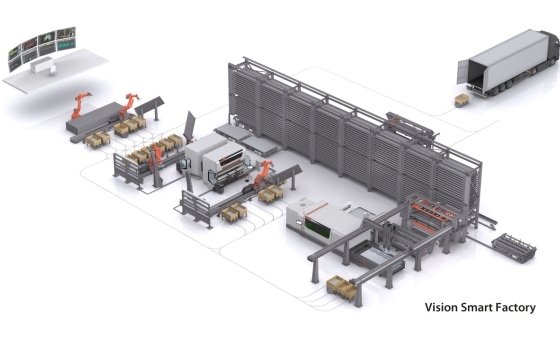

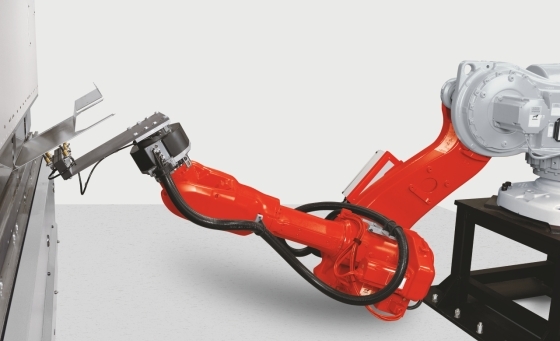

Automation

In an ever-changing world, automation becomes crucial. Bystronic offers automated solutions that improve not only productivity but also quality, guaranteeing optimum production with minimum intervention.

Eco-responsible technologies

Bystronic is committed to offering solutions that are not only efficient, but also respectful of the environment. Thanks to eco-responsible technologies, the company minimises its carbon footprint while guaranteeing optimum performance.

Training and education

Sustainability is not just about machines, but also about people. Bystronic believes in educating and training its employees, customers and partners to ensure the responsible and efficient use of its solutions.

Partnerships for a green future

Working together for a better future is essential. That's why Bystronic establishes strategic partnerships with other companies, universities and research institutes to promote sustainability in the industrial sector.

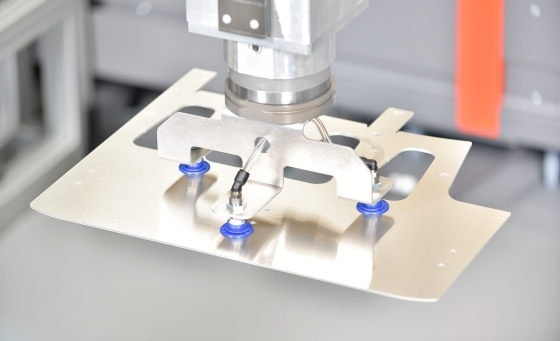

Flexibility and precision

Bystronic's laser cutting systems, such as the ByStar Fiber series, offer powers of up to 30 kilowatts, guaranteeing fast and precise cutting. Their adaptive cutting heads automatically adjust the focus for different types and thicknesses of material.

State-of-the-art technology

The machines incorporate edge detection technology, facilitating precise sheet positioning. In addition, their cutting control technology monitors and adjusts the cutting process in real time to avoid errors.

Solutions for all sizes

The cutting tables vary in size, offering options of up to several metres for processing large sheets. This makes them ideal for all kinds of applications, from precision parts to large components.

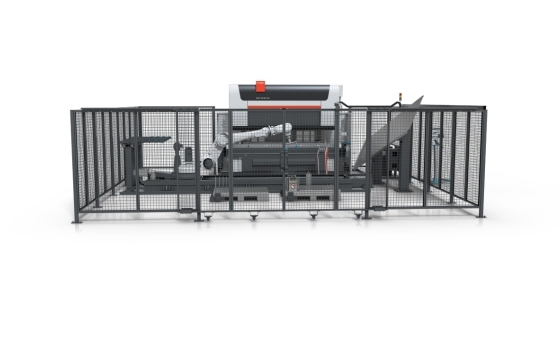

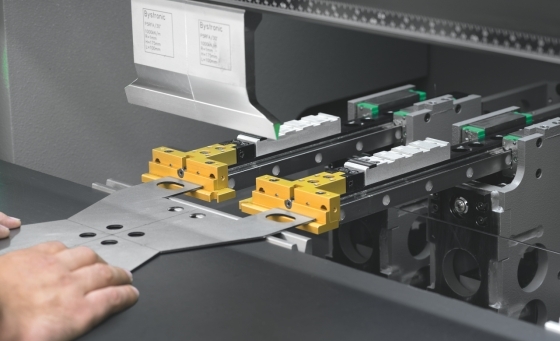

Precision bending

Bystronic press brakes, such as the Xpert Pro series, offer capacities of up to several hundred tonnes, guaranteeing a constant bending force along the entire length of the machine. Their real-time angle measurement system guarantees precise bending.

Ergonomics and safety

Safety features such as front laser scanners protect the operator while providing a clear view of the bending process.

Easy integration

Intuitive touch controls and integrated software allow rapid programming, job storage and easy integration with existing CAD/CAM systems.

Increased productivity

Automated solutions, such as ByTrans Cross, allow sheets to be loaded and unloaded automatically, reducing downtime and maximising efficiency.

Flexible solutions

Modular systems allow easy integration with existing cutting and bending machines. Their ability to handle a wide range of sheet sizes and thicknesses offers unrivalled versatility.

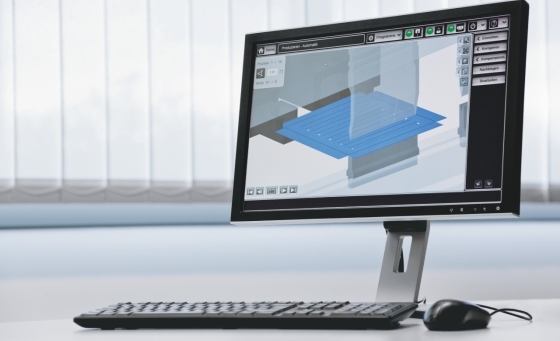

Intuitive interface

Control panels for automated solutions offer clear process visualisation, real-time diagnostics and on-the-fly programming capabilities, ensuring optimum use.