In a world of constant change, the sheet metal processing industry is no exception, and is constantly adapting. To find out more about current trends and potential solutions, Johan Elster, Chief Sales Officer Bystronic Group, talks to Metal-Interface. In this interview, he provides an insightful look at the challenges and opportunities facing the sheet metal working industry.

What challenges do you currently see in the sheet metal working sector?

The sheet metal working sector is currently moving in two major directions: digitalisation/automation and ecological sustainability.

Indeed, companies operating in this field are having to adapt their practices to changing market requirements:- fluctuating demand, characterised by small production batch sizes,

- an ever-shorter "time to market" to bring a product to market,

- rising raw material prices,

- and a shortage of skilled labour.

All these factors are inevitably leading to the adoption of the 'Smart Factory' concept.

At the same time, companies are also facing increasing environmental pressures, with a compelling need to reduce their carbon footprint, limit the rise in energy prices and manage resources more efficiently. These challenges must lead to better use of raw materials, as well as better management of residual sheet metal. The traceability of parts (quality, Green Steel, etc.) is also a key factor in achieving these objectives.

At the heart of this transformation is Industry 4.0, which is gradually evolving towards Industry 5.0, placing even greater emphasis on sustainability and the well-being of individuals. We are well aware of these challenges, and offer appropriate solutions, whether in the form of systems (machines), software or services.

How is Bystronic contributing to these challenges?

Our aim is to help our customers overcome these challenges and prepare them for the future. We aim to help them transform their businesses to make them more productive, digital and sustainable. This sustainability is materialised by increased energy efficiency, optimised use of resources, i.e. better use of sheet metal, less waste, and optimised and efficient processes. This in turn reduces energy costs and is perfectly aligned with the objective of digitisation.

Our solutions - machines, software and services - ensure efficient production through automation. As a result, downtime, stoppages and repetitive operations can be avoided, leaving staff free to devote themselves to other tasks. At the same time, it paves the way for increased production capacity through fully digitised and automated multi-shift working.

What potential do you see in your customers?

Firstly, we see immense potential in the area of digitisation. Many of our customers, particularly small businesses, are only at the beginning of this journey. Our aim is to help them stay competitive and at the cutting edge of technology through our innovative developments. The BySoft suite, specifically designed for the sheet metal sector, is an invaluable tool in this respect. It enables customers to digitise their entire business, from quotation to delivery. This not only involves automating production, but also managing processes after the cutting and bending phase.

The BySoft Suite offers every company in the sheet metal sector the opportunity to go digital, regardless of its size or current level of digitisation. The state-of-the-art technology offers a hybrid solution that combines cloud and on-premise software, making it affordable for small and medium-sized companies. The software can interact with third-party business management systems and machines, creating complete integrated solutions with a single data source.

BySoft Suite also supports our customers' sustainable development efforts. Thanks to BySoft, companies are improving their energy and resource efficiency, which translates into reduced production waste, lower energy requirements and more efficient use of materials.

Then there's artificial intelligence. AI is already in use here. Our R&D department designs components that are capable of learning, helping customers to avoid errors and maintain production processes. For example, the AI-controlled cutting process in the "Parameter Wizard" function of our laser cutting machines guarantees reliable quality, with low-manning production. But this is just the beginning. Our industry is still going to make huge strides in this area.

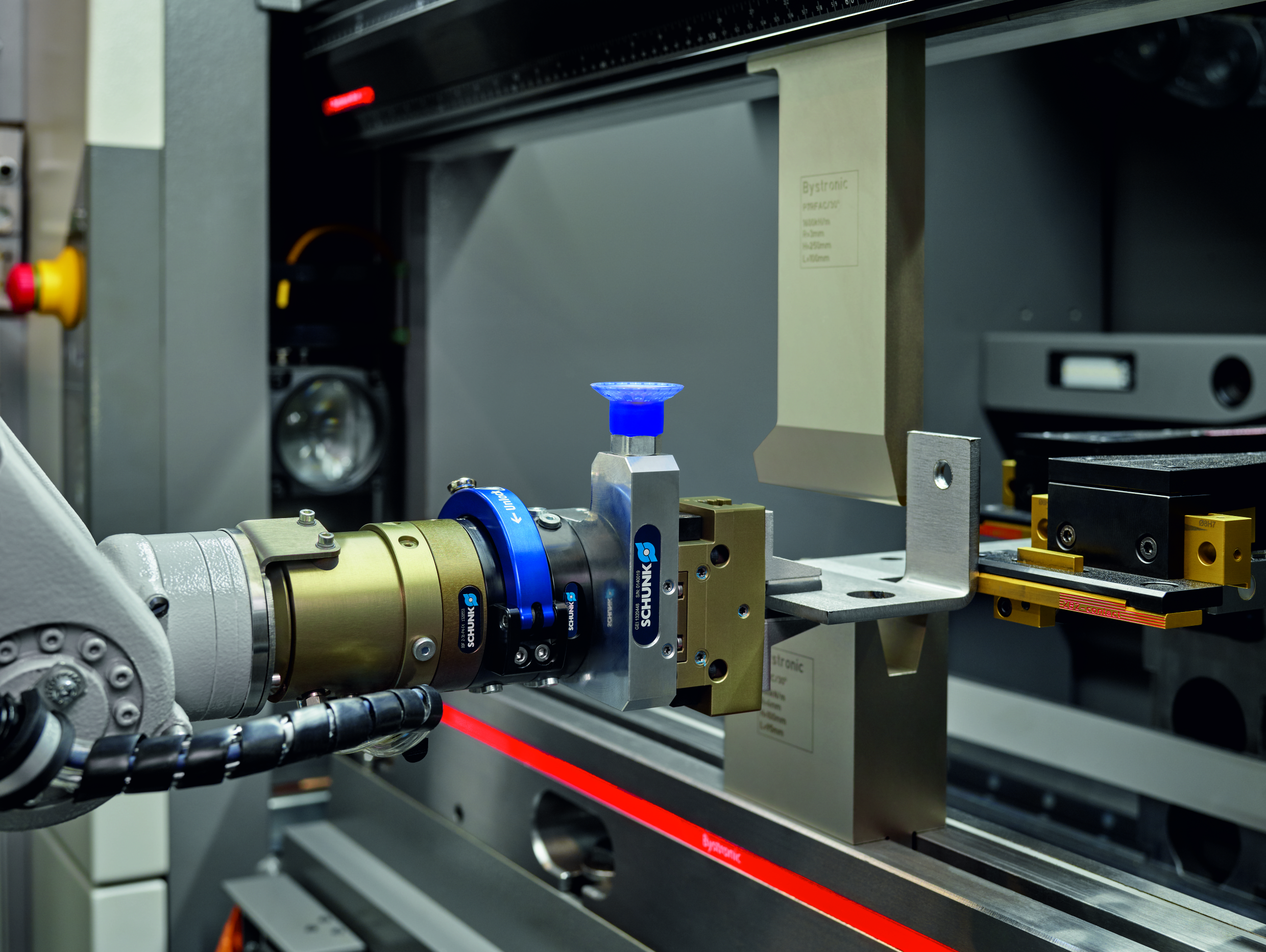

Secondly, in automation: many subcontractors are unaware of the potential that exists in this area. By using automation adapted to their machine, they reduce non-productive time and speed up processes such as loading and unloading the laser cutter or the press brake. And they can produce at times when staff are absent, such as at night or at weekends.

Today, we are already offering to build entire "smart factories". They operate virtually autonomously. What sounds like music from the future, we are already successfully implementing on the market.

In this period of transition marked by rapid progress towards digitalisation and sustainability, the interview with Johan Elster sheds valuable light on the major developments within the sheet metal industry. The echoes of this conversation point to a promising future where energy efficiency, waste reduction and advanced technologies are shaping a new industrial paradigm. At Bystronic, the commitment to facilitating this transition for companies of all sizes is clear, embodying a progressive vision that fuses innovation, sustainability and automation into a powerful synergy for a prosperous future.

Contenu