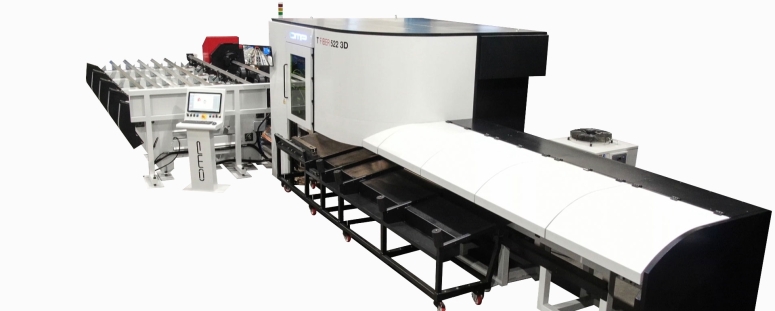

Since 1977 OMP has been a global partner for the entire tube and solid bar manufacturing process, from laser or disc cutting, to beam forming, to finishing with deburring, chamfering and threading lines. We also manufacture special machines tailored to the customer. At sheet metal 2022 we present the TF220 laser tube: this machine has been designed to meet the needs of our customers, TF220 processes tubes from 20 to 220 mm in diameter and bar loading lengths from 6 to 12 meters. In addition to 2D and 3D cutting, it produces holes and slots, markings and engravings, grooves, grooves, slots, joints, push-fit connections, cut-bend, on sections of round tube, square rectangle, elliptical, open profiles such as UPN, beams and angles , special boxed profiles and flat bars in brass, copper, carbon steel, stainless steel and aluminum alloys, cutting materials without burrs and respecting high quality standards. We are present at the Lamiera fair stand 13-B21. We are waiting for you!

The OMP tube laser TF220 uses a fiber laser source

The machine uses a fiber laser source, the laser beam hits the surface of the material and heats it to the point of melting or vaporising it completely. Once the laser beam has completely penetrated the material at a certain point, the actual cutting process begins. TF220 has several advantages such as great flexibility of use and high processing performance, precision +/- 0.01mm, low consumption, optimization of working times, reliability, efficiency and ease of use. The Industry 4.0 package present as standard on the TF220 ensures greater productivity through shorter set-up times, reduced errors and downtime. The TF220 tube laser offers machining freedom that no other tube cutting tool can offer.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

LAMIERA 2022 Press release

LAMIERA 2022 Press releaseTUBE LASER TF220 3D FOR MACHINING TUBES WITH LASER FIBER

Published on 19/04/22