The ZINSER CNC cutting systems are renowned around the world for its high quality and customized products “made in Germany”. ZINSER combines tradition with innovation and realises the needs of its customers. Our reputation as a world wide known company is based on our expertise in the field of flame cutting, and plasma cutting systems.

The ZINSER CNC cutting systems are renowned around the world for its high quality and customized products “made in Germany”. ZINSER combines tradition with innovation and realises the needs of its customers. Our reputation as a world wide known company is based on our expertise in the field of flame cutting, and plasma cutting systems.ZINSER offers more than just standard flame cutting machines.

With us you always get the leading technology.

Also, we provide you with the necessary tools to achieve optimal results possible.

ZINSER GmbH is your strong partner in the areas of flame cutting systems, oxy-fuel technology and hot air devices. Quality and the satisfaction of our customers are our first priorities. Name your task and we will find a solution together!

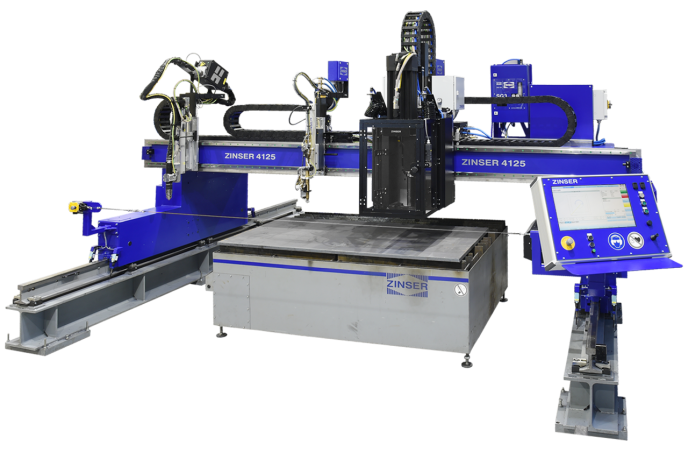

A ZINSER innovation: plasma and oxy-fuel bevel cutting on a single unit

Plasma cutting and flame cutting: 2 technologies which each gain their advantage depending on the thickness of the materials.

Oxy-fuel cutting occurs when the plasma process reaches its limits. But until now, the use of these two technologies on a single machine imposed space and cost constraints, by the presence of an additional torch carriage.

After long months of development, ZINSER offers here a revolutionary solution: ZINSER Switch Bevel. Its quick-change system makes it possible to switch from plasma torch to flame cutting torch in a few seconds, and therefore to perform chamfers on materials 1 to 300 mm thick, with angles of up to 60 °.

Thus, weld seam preparations on thick plates can now be carried out efficiently and quickly. This system offers maximum flexibility and an obvious productivity gain for your business.

The bevel unit features a magnetic quick release plate, on the plasma torch and on the flame cutting torch. In a few seconds, you replace the plasma torch with the flame cutting torch. The plasma torch is then positioned on standby on the ZINSER Switch Bevel unit. The 2 technologies can be used successively on already cut parts, or from a normal plate. The cutting thickness range is very wide, thanks to the presence of the flame cutting torch: up to 300mm for I cuts.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Optimise your processes Press release

Optimise your processes Press releaseZINSER Switch Bevel, plasma and oxy-fuel bevel cutting with a single unit

Published on 08/12/20