In 2018, welding fumes were classified as carcinogenic by the International Agency for Research on Cancer (IARC). In addition to cancer, the hazardous substances contained in welding fumes can also cause a variety of other serious illnesses, such as respiratory diseases and damage to the nervous system. With this solution, safe protection is offered by extracting directly at the point of origin, e.g. by extraction torches. It protects welders and other workers in every welding position as it prevents welding fumes from mixing with the breathing air.

ENGMAR has been producing and installing extraction and filtering systems for the metalworking industry since 1993. In addition to a large range of TIG and MIG/MAG extraction torches, ENGMAR offers ergonomic solutions for manual welding workstations. Various balancers and jib cranes reduce the weight and the risk of accidents at the workplace. The integrated engineering office continues to develop appropriate extraction systems to customers’ needs for manual, automatic and robotic welding workplaces.

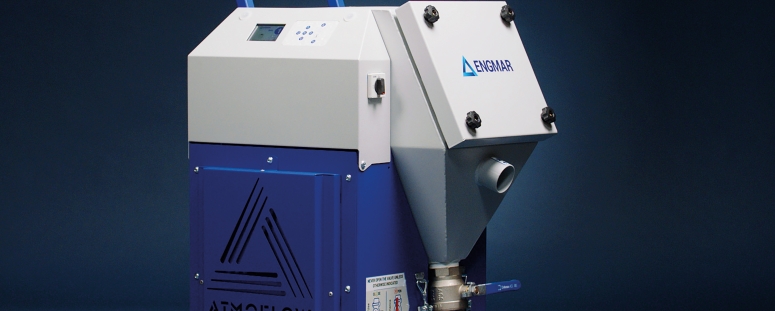

The new ATMOFLOW: safe and complete protection

The new high-performance extraction unit ATMOFLOW complies with the DIN EN ISO 21904 standard and guarantees optimum safety during daily work. It guarantees the induced speeds at the gas nozzle prescribed by the standard, which must be at least 0.25m/s for extraction torches up to 200A; and at least 0.35m/s for extraction torches over 200A. Compliance with these regulations guarantees the best possible extraction of the welding fumes.

Specially designed to filter out even the finest harmful welding fume particles, the ATMOFLOW extraction unit is the most powerful and efficient on the market. Its constant extraction power allows a treatment of up to 99.95% of welding particles of 0.3 ?m. Its program supports the operators in every step of the welding process by warning of key steps and points of attention via a digital display with lighted notifications and sound signals.

The ATMOFLOW is compatible with a range of products such as extraction torches or laminar nozzle (for MIG/MAG, TIG or MMA processes) for fume extraction at source and effective reduction of carcinogenic and toxic risks.

The unit has an automatic start/stop function that starts the extraction when welding begins. The unit cleans the extracted air and filters up to 99.999% of particles from a size of 0.3 ?m thanks to its two filters: a class M filter and a HEPA fine dust filter H14.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

EuroBLECH 2022 Press release

EuroBLECH 2022 Press releaseENGMAR presents a new extraction unit to protect welders

Published on 07/10/22