Timesavers International is the worldwide specialist with more than 80 years of experience in sanding and grinding machines for deburring, edge rounding (possible up to 2 mm radius), finishing, laser oxide and/or metal slag removal and precision grinding. Together we strive for the highest quality and finest finish of your sheet metal products. Our metalworking solutions are completely built according to your wishes, and the possibilities are endless. The range of machines varies from small entry-level deburring machines to large finishing and precision grinding machines. In addition, we offer training, service and support so that you can get the most out of the machine and we like to keep you informed through webinars. Discover Timesavers’ solutions for efficient deburring and consistent results at the EuroBLECH in Hanover this October.

Timesavers rotary brush machines for edge rounding

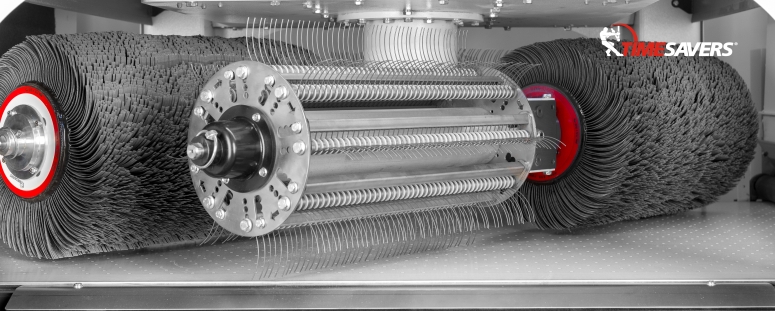

Timesavers is proud to show the latest version of the compact rotary brush machine: the 32 HWRB series. Not only has the rotary brush carousel been optimised, but the machine also has an additional feature: the Hammerhead. The popular rotary brush technique is the ultimate solution for creating a uniform radius on all edges of sheet metal parts up to a width of 1100 mm. It is even possible to combine edge rounding with the removal of oxide skin on steel parts. The 32 series HWRB will be equipped with a dust extractor Timesavers x Absaugwerk.

Moreover, the 22 RB series with pictogram control will be presented. The machine has a working width of 600 mm and is a great solution for companies that produce on a smaller scale. The results are perfectly deburred and rounded parts.

Of course, the large 42 RB series with its industry 4.0 functionalities must not be missed at this event either. The machine is the largest deburring machine, available in a working width of 1350 and 1600 mm. With the two grinding belts at the beginning of the machine, it is a great solution for removing large burrs. The machine can also create a radius of 2 mm on parts with the eight rotary brushes, to ensure the quality of coating and painting.

Other deburring machines on display at the EuroBLECH

The 12 series WB is a starter model with 600 mm working width for deburring and finishing of small parts. This machine has an abrasive grinding belt and brush.

Last but not least, you can find the entry level model deburring machine, the 10 series Manual Grinder, at Timesavers’ stand. This solution is 3 to 4 times faster than deburring by hand, and very easy to use. It also makes the processing of product a lot more fun to do.

Ready to become more efficient? The Timesavers team and dealers are all looking forward to help you find the right solution that fits your production process.

We kindly invite you to visit us at the EuroBLECH from Tuesday 25 until Friday 28 October in hall 14, at stand L41.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

EuroBLECH 2022 Press release

EuroBLECH 2022 Press releaseEfficiency and consistency in deburring process with Timesavers

Published on 15/09/22