Pronic offers tapping and insertion solutions that fit into your existing In-Die solutions. Sometimes you are no longer satisfied with this existing In-Die equipment, whether it was developed in-house or purchased from a manufacturer.Pronic has the solution you need! We are able to integrate our solutions to optimize your production tool.

Do you want to increase your efficiency?How does Pronic support you in your projects?

From the design stage to the start-up and optimization of your new In-Die solution, Pronic remains your privileged partner.

For tapping solutions, the choice of the solution is to be discussed together, often linked to the tool configuration, available space, production and equipment reutilization strategy, etc.

For insertion systems, beyond new equipment, it is also possible to reuse existing equipment and integrate it into our solutions to limit investment costs

The goal: To make the most of every press stroke!

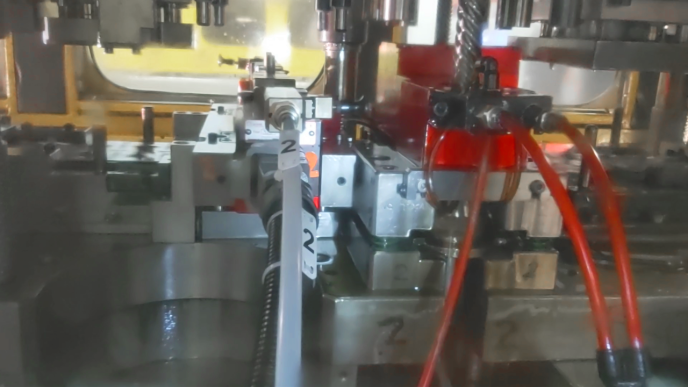

Example of an action at a customer's site for in-die insertion

Customer issue

Recently, a customer contacted us because he was no longer satisfied with his pin insertion system installed in a tool (company already equipped with Pronic tapping machines).

Before retrofit The project constraint

The specificity of this project was to be able to reuse the vibrating bowl distribution system.

The Pronic solution

After a study by the engineering department, our team designed a distribution cart to integrate the customer's vibrating bowls. Then we conceived a new insertion head adapted to the tool.

An efficient tool

After installation and training of the team, this complete redesigned insertion system is now reliable and much more efficient.

The production rate is 45 strokes / min, beyond the customer's expectations.

After retrofit Do you have an In-Die insertion or tapping project?

Pronic is your contact, wherever you are in the world. Just contact us!

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Global-Industrie 2022 Press release

Global-Industrie 2022 Press releasePronic solutions can be adapted to your existing tools!

Published on 01/04/22