Adira Metal Forming Solutions, with its more than 60 years of history as a benchmark manufacturer and global supplier of engineering solutions, is positioning its brand more ambitiously and competitively, reformulating marketing and communication organisation and strategy to shore up its position worldwide.

“Shaping the future” is the company's new slogan, with a focus on new technology to mark the change in positioning, which is in line with its mission to satisfy its customers' needs and provide innovative solutions.To grow its leadership position in the Iberian Peninsula into a multi-continental presence, by leveraging a geographic proximity that channels the competitive advantages of each of its global partners, ADIRA is now more accessible, more effective and more ambitious. Opening a physical and virtual showroom and designing an augmented reality app are just some of the innovations introduced with the rebranding at www.adira.pt., The company has also decided to study its performance through customer reviews, case studies and white papers, and to provide increasingly more optimisedpand automated customer service.

ADIRA specialises in the production of hydraulic, electric and hybrid press brakes, shears and robotised cells and conducts intensive research and development in large-scale additive manufacturing. The company was acquired by Sonae Capital in 2017 and has since increased the portfolio of services, automation and customised solutions it has to offer, focusing on digital restructuring and transformation. ADIRA now embraces the challenges of the future more effectively and successfully.

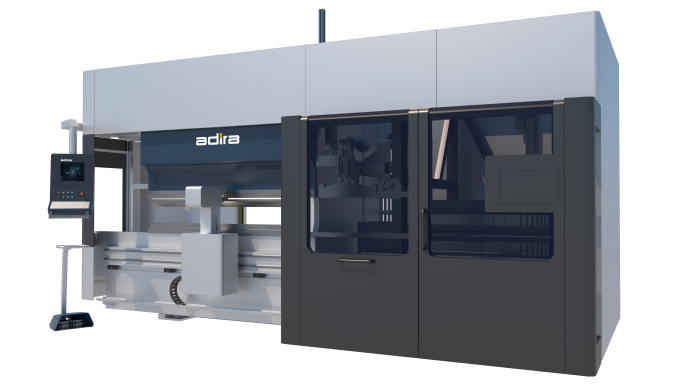

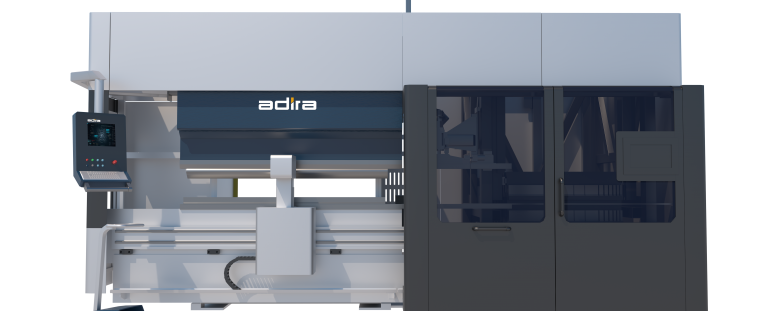

Press Brake with an Automatic Tool Changer Solution

The automatic tool changer solution is an innovative device designed to allow tools (upper and lower) to be changed automatically, saving time and increasing efficiency.

This system allows you to:- Manage the tools needed for bending. The system selects and positions the tools and dies available in the automatic tool warehouse, avoiding the manual selection and changing of tools and dies.

- Automatic Laser: Finds the ideal tool in the machine or in the warehouse

- Storage capacity between 32 and 52 metres of tools

- Tool storage management interface on the controls

- Cleans the tool system and work table.

BenefitsThis system can feed 1 (single) or 2 (twin) press brakes. The following options are available:

- ATC S32 – Single Tool Replacement System capable of storing 32 metres of tools.

- ATC S52 – Single Tool Replacement System capable of storing 52 metres of tools.

- ATC T52 – Twin Tool Replacement System capable of storing 52 metres of tools.

Flexibility- Any tool part in the press brake can be replaced without all the parts having to be removed sequentially

- Large size of tool parts (max. 515 mm), which means less system movement, making it much faster

Reliability- Cleans the tool system and work table, keeping bending quality and precision at maximum levels

Scalability- The “Twin” option or upgrading to “S52” can be retrofitted, as long is this is provided for initially

- The number of magazines can be reconfigured or changed, according to the customer's needs

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Optimise your processes Press release

Optimise your processes Press releaseADIRA FOCUSING ON REPOSITIONING TO SHORE UP ITS POSITION WORLDWIDE

Published on 02/10/20