Linde’s latest sensor technology will enable customers to have an uninterrupted gas supply that can be managed remotely. Meet DIGIGAS®.

Linde’s latest sensor technology will enable customers to have an uninterrupted gas supply that can be managed remotely. Meet DIGIGAS®.

The invention of the dashboard fuel gauge was a key moment in the history of the automobile. Today no car is without one. Whether a dial with a moving pointer needle or a modern digital screen, these gauges revolutionized the day-to-day life of drivers, letting them know when to fill up before they run out.

In the world of gases, the contents of a cylinder can unexpectedly run out, and needs to be repeatedly checked to ensure this does not happen. At present, this is done manually at the point of use – daily, weekly or monthly – with new cylinders ordered when required. But this could be about to change.

Responding to customer needs and requests, the Linde Technology Team has developed a smart gas management system with exciting possibilities. DIGIGAS® monitors the gas content of cylinders remotely (and continuously) and enables the customer to view this data anytime, anywhere. The system also means that Linde can offer automatic cylinder replenishment to their customers.

In other words, it provides customers with an uninterrupted gas supply.

Under pressure: From the cylinder to the cockpit

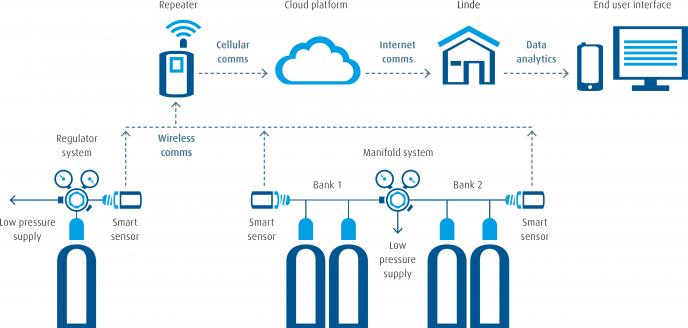

“We connect smart sensors to the gas equipment that is attached to the cylinders. This can be done quickly and easily,” explains Linde Global Project Manager Chris Cowles. The sensors can be fitted to a pressure regulator or a manifold, or even to single cylinders if they have a pressure port. The sensors then monitor the pressure within the cylinders and transmit the information to a cloud platform via a repeater. This data is made available to Linde customers in a web-based end-user interface, known as the cockpit.

“The gas content of cylinders is always communicated as a percentage,” says Cowles. When the percentage reaches a certain level, customers can receive a notification via email or SMS. “The level at which this happens can be set by the user,” he adds.

And it doesn’t have to end with a notification. DIGIGAS® in fact comes in three different packages. While DIGIGAS® Notify keeps customers in the loop when it comes to gas-content levels, the second service level goes one step further. DIGIGAS® Order automatically reorders cylinders – thus removing another manual step in the process.

The third option is known as DIGIGAS® Total. As the name suggests, this is the full-service option for Linde customers. Here, the connection of new cylinders and the collection of old ones is also taken care of.

“Each service offer is designed to match specific market requirements,” explains Christine Kandziora, Commercialization Director Spec Gases at Linde. DIGIGAS® can be applied to institutions with stationary systems on site, such as research labs, or larger companies that provide gas to individuals such as welders. In the second case, a centralized system ensures that everyone has access to the information as and when they need it, rather than relying on communication between the different people involved.

“While not sector specific, DIGIGAS® is particularly well-suited to manufacturing, research and the automotive industry,” says Kandziora.

The smart sensor can also be attached to the manifold Efficiency gains all round

“First and foremost, DIGIGAS® boosts efficiency,” Kandziora explains. It saves time when it comes to keeping stocks in check, as well as time and costs that could be lost should the supply to a critical process unexpectedly run out.

It also improves the efficiency of the entire supply chain. By providing a better overview of requirements across the Linde network, DIGIGAS® allows deliveries to be better predicted and coordinated. Over time, this results in more logical route planning and fewer unnecessary journeys – something that can only be good for the environment.

Unlike some new technologies or innovative products, DIGIGAS® can be retrofitted to existing systems, making it simple and almost undisruptive for customers who want to start using it.

Contenu