The AFUludine solution is a patented French innovation that is part of an ecological approach. An alternative to petroleum products that makes it possible to meet the challenges of our planet and anticipate future environmental restrictions. The choice of a high-performance product for manufacturers. We want to offer manufacturers ecological lubricants intended for the problem of "shaping metallic materials" to eliminate the degreasing phase. This allows our customers to reduce their costs by limiting their water and electricity consumption and thus being more environmentally friendly. Our complete product range is designed specifically for the needs of industrialists and we offer a turnkey solution with a spray system perfectly adapted to your production line. We are a manufacturer and specialist in Research and Development, which allows us to produce tailor-made products from specifications given by our customers for specific requests.

An innovative and sustainable lubrication technique.

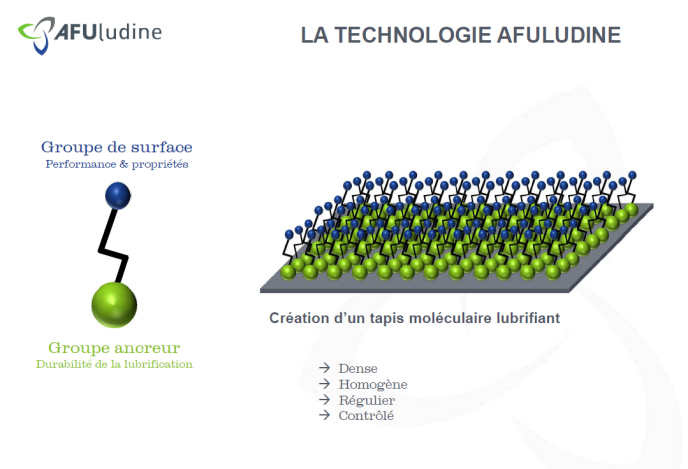

AFUludine synthesizes its active molecules for lubrication. (Patent WO2016046401)

A strong bond with metal

The molecules have on the one hand an anchoring group that has a great affinity with the metal. This characteristic feature will create a strong bond and ensure the durability of the lubricant during shaping. On the other hand, the surface function will allow optimal lubrication.

A lubricating molecular layer

When the lubricant is in contact with the metal, the molecules providing the lubrication are grafted onto the substrate. In a few seconds, the molecules will organize themselves and form a lubricating molecular layer.

Slip phenomenon

Slip phenomenonWhen the application liquid evaporates (100% biodegradable alcohol), a molecular cluster will be created. This molecular organization will form a scale structure that will allow the necessary sliding between the two metal surfaces.

Today, the AFU Industrie range significantly reduces friction and preserves both the metals treated and the tools used.

A complete range of products conceived for metal working

AFUludine offers a full range of non-oily lubricants for manufacturers. This lubrication can be done in dry or wet form and will allow you to carry out your metal shaping work.

The gains for manufacturers can be multiple:

The gains for manufacturers can be multiple:- Remove the degreasing step

- Limit associated waste reprocessing

- A gain in working comfort

- Reduce process time

- Save energy

- Condition the parts directly after shaping

- Gain in performance

The lubricants are specifically designed for stamping, cutting, laser cutting, flow forming, tapping, bending, bending, tube forming, calibrating, punching, profiling, final lubrication on products finished...

In addition, we offer a range of degreasers and cleaners developed mainly for metals. Certified free of hydrocarbons, chlorine, alkanes, or toxic aromatic compounds, these products can be used to degrease metals.

Our products are suitable for different sectors of activity such as automotive, watchmaking, connectors, aerospace...

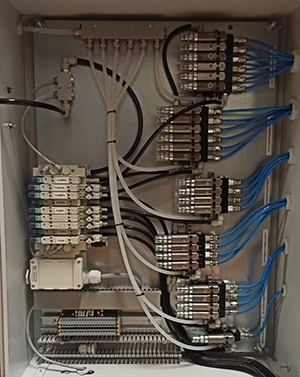

The establishment of a suitable application system

AFUTECH application systems are designed specifically for our non-oily lubricants. Adaptive and made-to-measure, our devices allow efficient and controlled application of products on your parts to be shaped. Complete or partial systems, our AFUTECH range will perfectly meet the expectations and challenges of the industrial world.

Contenu