Metal-Interface recently sat down with Soroush Karimzadeh, CEO and Co-Founder of Novarc Technologies, to discuss the prevalent challenges faced by companies in the sheet metal industry. Novarc Technologies, under Karimzadeh's direction, has been at the forefront of innovative solutions, particularly in the realm of welding automation.

The Global Welder Shortage: A Deepening Crisis

The most significant challenge currently afflicting the sheet metal industry, according to Karimzadeh, is the global shortage of skilled welders. In North America alone, there's a staggering deficit of 400,000 welders, with Australia reporting a shortage of 70,000 by 2030. This gap between demand for welding services and the supply of skilled welders has forced the industry to pivot towards alternative solutions, primarily automation.

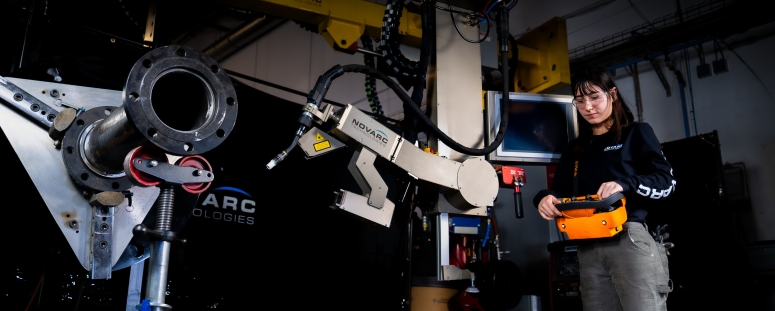

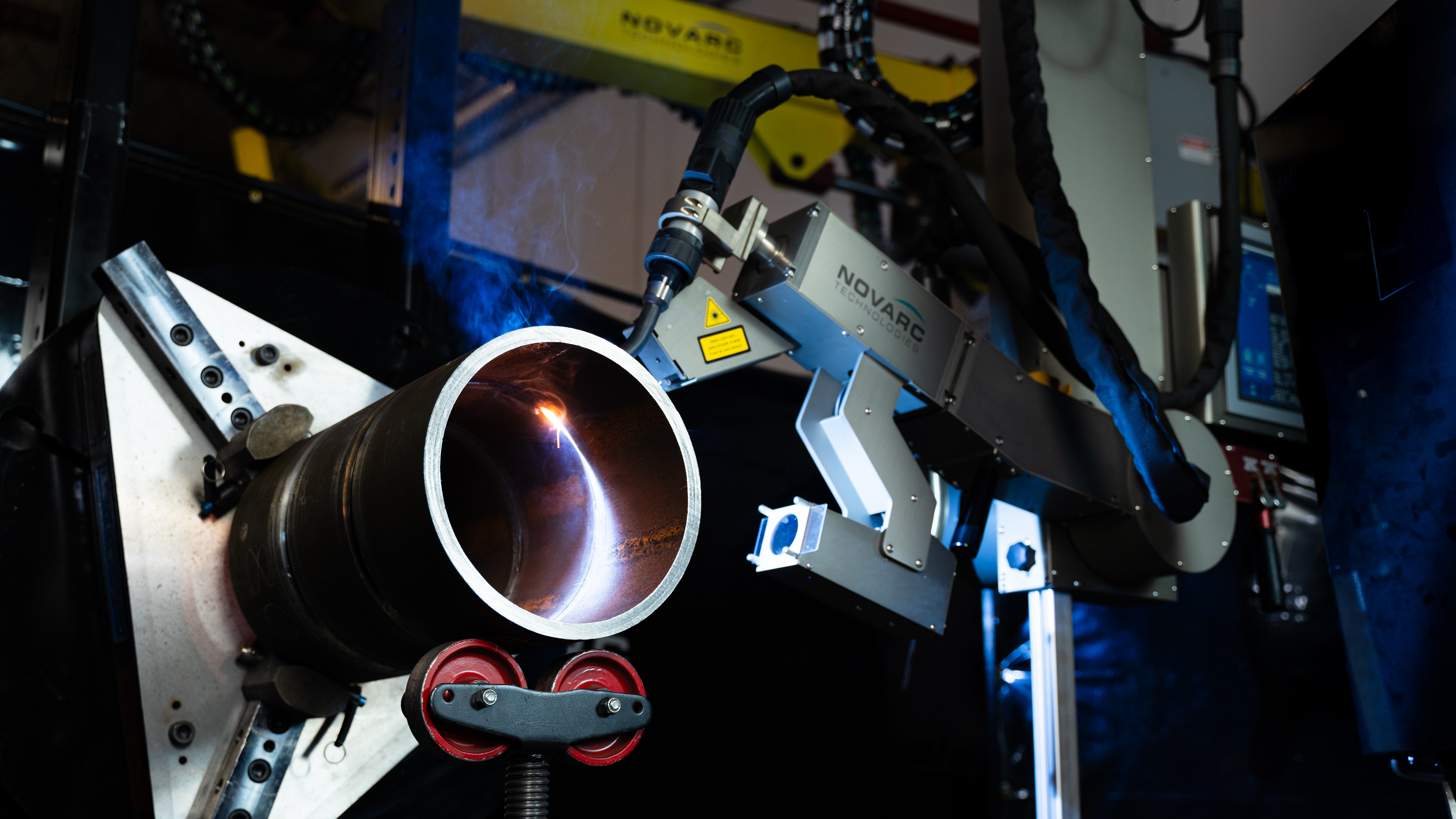

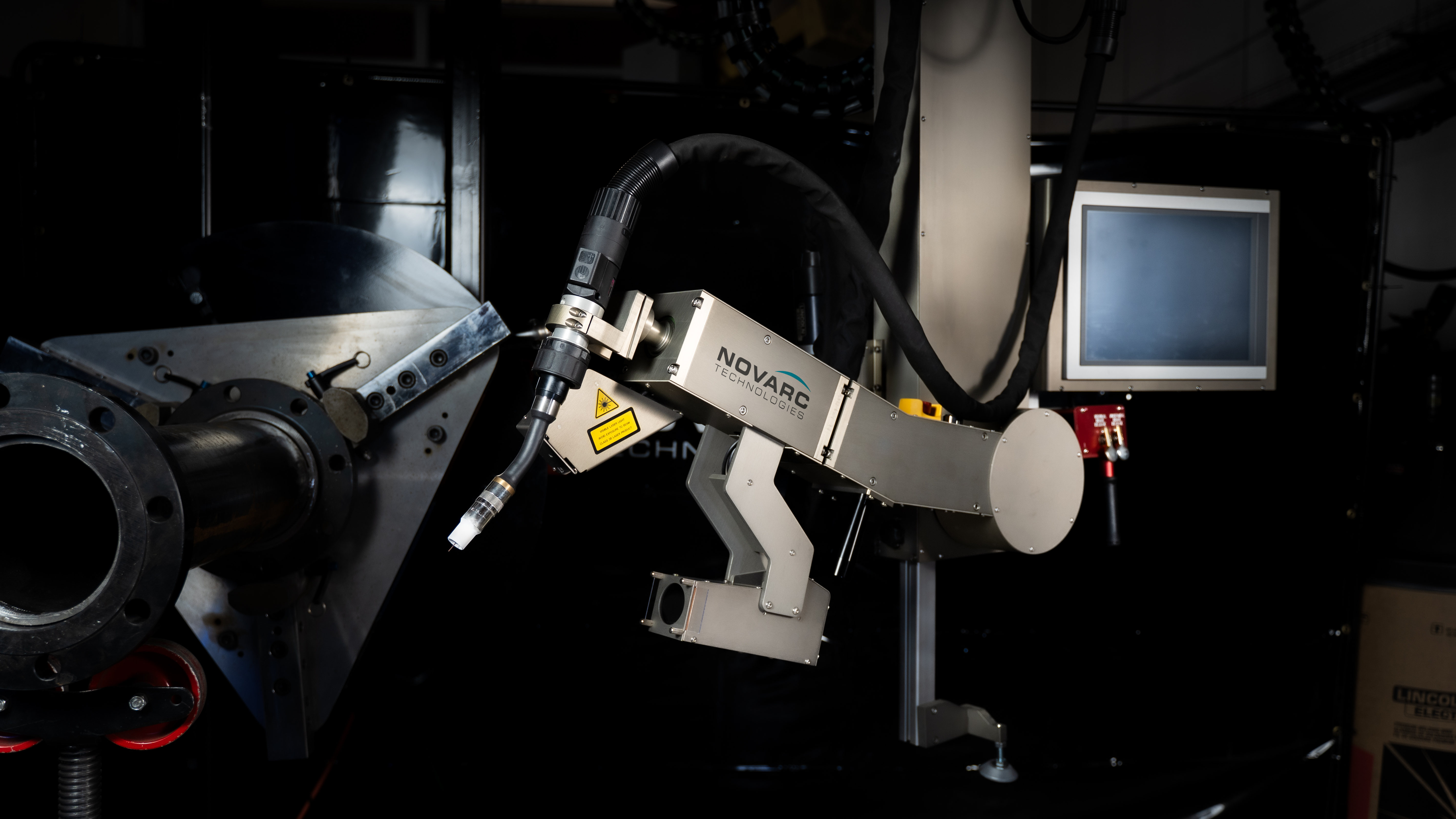

Rise of the Cobots: Bridging the Productivity Gap

One of the most notable trends emerging from this shift to automation is the rise of cobots, or collaborative robots, designed to work in conjunction with human operators. These welding cobots, as showcased by Novarc Technologies, promise to alleviate some of the pressures borne by the industry. With the introduction of advanced robots like Novarc Technologies's "Spool Welding Robot" a single human welder is achieving a 3-5x increase in pipe welding productivity. Beyond sheer productivity, these robots also guarantee improved weld quality, boasting less than 1% repair rates, where the average repair rate of pipe fabrication shops is typically 3-5% with highly skilled welders.

High Interest Environment: The Capital Conundrum

Karimzadeh also highlighted the financial challenges faced by companies, especially in the current high-interest environment. With capital being tied up in ongoing projects, finishing projects faster and freeing up resources becomes paramount. This is where automation technologies play a pivotal role, eliminating production bottlenecks and enabling companies to deliver faster and bolster their working capital.

A Worldwide Phenomenon, with Regional Nuances

While automation is touted as a universal solution, its adoption varies across regions. Developed countries in Western Europe, North America, and Australia are leading the charge. However, regions like China and the Middle East are grappling with distinct challenges of their own.

Interestingly, the push for automation is also fueled by global initiatives like carbon capture technology and the urgent need for renewable energy infrastructure. These initiatives demand specialized welding procedures, which further accentuates the need for skilled labor and automation.

The Talent Challenge: Why Skilled Labor is Scarce

Delving deeper into the issue of the welder shortage, Karimzadeh identified several factors at play. Attracting new talent to trades such as welding is becoming increasingly difficult, especially with an aging population of welders. In North America, the average welder's age stands at 55 years, with many nearing retirement. Moreover, grooming new talent is a lengthy process. Aspiring welders require up to 4 years of training to achieve proficiency, further exacerbating the industry's labor shortage.

Novarc Technologies's Pioneering Solution

In response to these challenges, Novarc Technologies introduced the world's first welding robot in 2017, heralding a new era for automated welding cobots. Designed explicitly for automating pipe fabrication, this robot offers a tailored solution for industries ranging from high-rise construction to oil and gas. With such innovations, Novarc Technologies's clientele can significantly enhance productivity, improve weld quality, and expedite delivery timelines.

Conclusion

The sheet metal industry, like many other sectors, is in a state of flux, grappling with labor shortages and the pressing need to adapt to technological advancements. Companies like Novarc Technologies are spearheading the charge, offering innovative solutions that promise not only to address current challenges but also to pave the way for a more sustainable and efficient future.

Contenu