Carrosserie Vincent, the historic entity of the Vincent Group, employs 193 people at its site in Étoile-sur-Rhône (26). Specializing in bodywork for HGVs (heavy goods vehicles), light vehicles, buses, and coaches, it also designs equipment for the environment and transport.

Stéphane Crespin, Site Manager, and Kenny Payet, Head of Cutting Operations, shared with Metal-Interface the progress made in modernizing and automating their production workshop.

A Need for Technological Development

Before investing, Carrosserie Vincent operated with a Beyeler press brake, Bystronic's historic brand, which was almost 25 years old. It also had a plasma machine, but this equipment no longer met the growing market demands, particularly regarding production capacity.

A large share of the laser cutting and bending was outsourced locally, resulting in dependence on external service providers, increased costs, and longer production lead times. Moreover, this organization did not provide the flexibility necessary for business development.

Faced with these constraints, the company decided to bring production in-house to:

- Improve control over lead times and responsiveness.

- Reduce costs by limiting outsourcing.

- Gain flexibility by producing on demand.

3- Choosing a Laser Cutter: An In-depth Analysis

To select the machine best suited to its needs, Carrosserie Vincent conducted a comprehensive comparative study, consulting several manufacturers and relying on detailed specifications. Tests were performed under real production conditions: sheets were sent to the various manufacturers to assess essential criteria, particularly cutting quality.

Stéphane Crespin reflects on this decisive phase:

"We had no prior knowledge of laser technology. The support of Philippe Garcin, our contact at Bystronic, was crucial. He not only helped us better understand the technology but also opened up new perspectives by introducing us to functionalities we hadn't imagined."Key selection criteria:

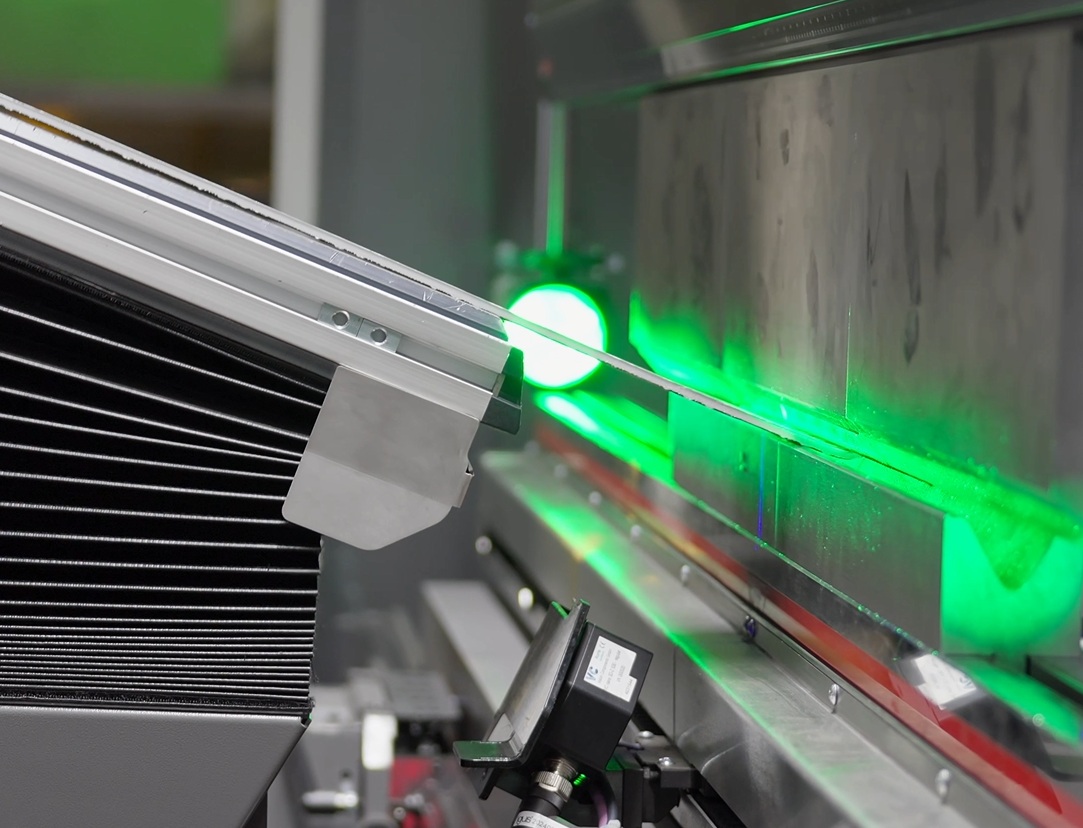

- Unrivalled drilling quality

"Thanks to a special nozzle equipped with an advanced focusing system, our machine can drill in a single pass, even on thick sheet metal up to 20 mm. Bystronic was the only manufacturer offering this technology. It ensures better thermal stability, limits spatter, and guarantees clean, regular cutting without deforming the material. This precision allows us to avoid a machining stage," explains Stéphane Crespin.

"Thanks to a special nozzle equipped with an advanced focusing system, our machine can drill in a single pass, even on thick sheet metal up to 20 mm. Bystronic was the only manufacturer offering this technology. It ensures better thermal stability, limits spatter, and guarantees clean, regular cutting without deforming the material. This precision allows us to avoid a machining stage," explains Stéphane Crespin. - Precise, clean cutting

The company mainly works with Magnelis sheet metal between 3 and 6 mm thick, an anti-corrosion steel treated throughout. The cutting quality had to be impeccable to avoid any risk of oxidation, which the tests confirmed. - Controlled cost optimization

Another key criterion for Carrosserie Vincent was the cost per meter of cut. A comparative analysis considered energy consumption, consumables costs, and machine productivity. - A global automation project

Stéphane Crespin explains:

"The integration of this laser machine is part of a broader approach to modernizing the workshop. We have implemented an automated storage system comprising 11 cassettes for incoming raw materials and 2 cassettes for outgoing machined parts. The result: a smooth material flow and a drastic reduction in manual handling. Moreover, the machine can operate entirely autonomously, particularly at night."

An additional advantage: the storage tower is well-designed and allows easy maintenance, thanks to optimized access to sensors and essential components.

- Laser marking: a strategic advancement

"The integration of engraving has completely transformed our organization. We use it to ensure optimal traceability of parts, mark welding and assembly points, and more. Even better, our Bystronic machine allows us to choose between surface or deep engraving, depending on whether the marks should remain visible after painting or not," notes Stéphane Crespin.

- Compact Machine: a decisive advantage

Finally, one last factor played a decisive role: the machine's footprint. Unlike other competing solutions, the Bystronic machine fit perfectly into our factory layout without requiring major modifications.

- Unrivalled drilling quality

4- The Choice of Press Brake

The choice of a Bystronic 250-tonne press brake for bending sheet metal up to 8 mm thick was a natural one for Carrosserie Vincent. The decision was based on production trials, including a test involving the production of nesting boxes with holes requiring perfect alignment.

"We wanted to control bending precision, even on complex parts," explains Stéphane Crespin. "The Bystronic machine met these requirements perfectly."

A powerful software for seamless integration

One decisive feature of this press brake is its advanced software, which integrates directly with the design office.

"It saves us a lot of time: we can query the system from the design stage and avoid costly back-and-forth between the design office and the methods office."

The software also calculates bending losses, optimizing production in conjunction with laser cutting.

Precision and ergonomics: major assets

- Integrated angle measurement: Bending precision is critical, and the integrated angle measurement system ensures great reliability. Bystronic stands out with a well-integrated and protected system that prevents untimely impacts with the part being bent. Attention to the rolling direction is no longer necessary.

- Dynamic hydraulic crowning: This system adjusts bending parameters in real-time to compensate for material variations. "This results in uniform bending, with no surprises during production," emphasizes Stéphane Crespin.

- Optimal ergonomics and ease of use: The intuitive CNC and folding aids enabled operators to quickly adopt the machine.

"From the very first use, the machine proved very intuitive. A bender who had been working with our old machine for 25 years adopted it effortlessly," adds Stéphane Crespin.

- Design adapted to large parts: The apron opening, with an additional 200 mm, "allows us to manufacture larger boxes without constraints," says Stéphane Crespin. This feature expands production capabilities and simplifies working with large parts.

5- Conclusion

The investment made by Carrosserie Vincent marks a major transformation of its production workshop. By bringing critical stages like laser cutting and bending in-house, the company has significantly reduced its reliance on subcontractors, improving lead-time control and production flexibility.

This transition has also had a direct impact on costs, achieving a 40% reduction in part prices compared to previous subcontracting.

Integrating advanced technologies and automating processes has further improved working conditions for operators and strengthened the company's brand image.

By combining innovation, automation, and expertise, Carrosserie Vincent is positioning itself as a competitive industrial player, ready to meet the technological and economic challenges of tomorrow.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

- Optimise your processes Technical article

Carrosserie Vincent: Automation and Insourcing of Laser Cutting and Bending

Published on 05/05/25