Harald Langeder Member of the Executive Board, CTO - FRONIUS The lack of qualified staff is one of the biggest challenges facing the metalworking industry in Europe and worldwide. Studies such as those by the ifo Institute and the EY SME Barometer 2025 show that there is a shortage of qualified personnel, particularly in welding, with significant consequences for productivity and competitiveness.

The reason for this shortage would be, on the one hand, that the training systems for these professions are not sufficiently adequate and, on the other hand, that even people already active in professional life have difficulty carrying out complex tasks. Consequence: the labour market has fewer and fewer qualified people capable of assembling components with the high quality required and in accordance with the ever-increasing standards requirements. Digital and automated welding solutions can make an important contribution in this area.

Solutions for "Fach" and "Kraft"

In German, “skilled workers” are called “Fachkraft”. In the search for solutions to close this qualification gap, it is worth dividing the term ‘Fachkraft’ into two words “Fach” and ”Kraft”. Whereby Fach stands for the know-how, experience, and skills of the employees and Kraft represents, so to speak, the work force, i.e., the amount of people available.

If we consider the theme Fach, it's about training specialists faster and better and making their day-to-day tasks easier - for example, handling welding torches. The watchword for the welding training of the future is therefore: minimal training time and optimised work processes. Modern welding workstations must not only provide innovative technologies, but above all be simple and intuitive to use in order to offer maximum support to users.

With regard to the theme of Kraft - i.e. the limited availability of skilled workers - automation has great potential. However, access to this area must be facilitated so that it is also profitable for small and medium-sized enterprises and for small quantities.

AI in the training of professionals

Thanks to augmented reality, 3D glasses and real welding equipment, modern virtual welding training is now particularly effective, practical and of a high standard. Today, around 80% of component-related training can already be carried out on a simulator.

Thanks to augmented reality, 3D glasses and real welding equipment, modern virtual welding training is now particularly effective, practical and of a high standard. Today, around 80% of component-related training can already be carried out on a simulator.This makes it easy to learn manual dexterity and, in most cases, basic theory. The advantages of this largely virtual training are obvious: no material for practice pieces is required, and there is no risk of welding spatter, heat, smoke or glare to the eyes. On the other hand, virtual coaches provide support and immediately indicate if, for example, the angle of attack of the torch or the speed at which it is guided is not correct. This makes welding simulation an attractive and safe way of training professionals and speeding up training.

Weld sequencing for quality assurance

Of course, the symptoms of the lack of skilled workers are also continuing in production. Here, digitalisation is enabling innovative ideas and concepts to be implemented to reduce the complexity of tasks for welders.

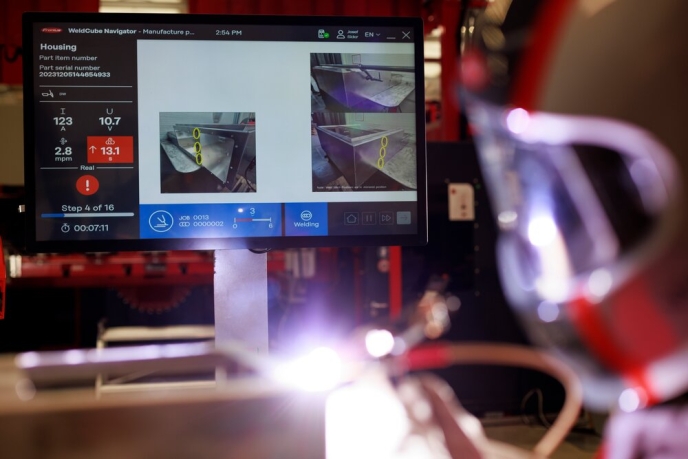

Digital welding plans, also known as Weld Sequencing, are one possibility. Complex tasks are broken down into partial work steps, while ensuring that they are carried out to standard thanks to correctly assigned welding parameters. The welder then follows the step-by-step instructions that he sees in front of him on a screen. If a quality-critical error occurs, the process is immediately interrupted and the welding supervisor is informed - even before subsequent errors occur. This reduces production errors and costly rework.

Automation where staff is lacking

The most important way of dealing with the shortage of qualified workers is to automate production. Compact cobot cells are particularly popular. These are equipped with collaborative robots that allow man and machine to work very close together. Cobots are a very good choice as a first step in automation, especially for small and medium-sized businesses. Not least because the use of cobot cells is already economically viable for small batches.

For the manufacture of more complex parts in very large numbers, it is advisable to use individual welding systems, or even complete welding cells, which are assembled according to the company's requirements. Priority is always given to the optimum interaction between functionality and cost-effectiveness.

For the manufacture of more complex parts in very large numbers, it is advisable to use individual welding systems, or even complete welding cells, which are assembled according to the company's requirements. Priority is always given to the optimum interaction between functionality and cost-effectiveness.

Competitive thanks to digitalisation and automation

In conclusion, the lack of qualified staff in welding is not a temporary phenomenon. Rather, it is a structural problem that is having a major impact on the competitiveness of metalworking companies. To deal with it, companies will have to improve their efficiency.

Thanks to digitisation, they can optimise training and reduce learning times. Easy-to-use welding workstations equipped with assistive technologies also mean that productivity can be maintained despite a few vacancies. Additionally, automation effectively compensates wherever skilled labour shortages exist.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Welding technologies Guest columns

Welding technologies Guest columnsAnswers to the lack of qualified staff

Published on 16/06/25