In the hallways of your company, the rhythm of production echoes like a heartbeat. Here, where sheet metal becomes components, and components become products, the game is no longer played on a single machine—it’s played across the entire system. And in this game, the rules are changing fast.

In the hallways of your company, the rhythm of production echoes like a heartbeat. Here, where sheet metal becomes components, and components become products, the game is no longer played on a single machine—it’s played across the entire system. And in this game, the rules are changing fast.Today’s manufacturing landscape is shaped by twin pressures: a shrinking labor pool and an accelerating market. Deliveries must be faster. Batches must be smaller. Customization is the norm, not the exception. Meanwhile, skilled labor is vanishing, and even the most advanced machines cannot run without context—without a system that makes sense of what comes next.

So we asked ourselves: how do we stay efficient, agile, and competitive in a world that moves faster than a paper job list? The answer is not more machines. It’s more intelligence between them. It’s end-to-end process management.

The silent crisis: disconnected intelligence

Let’s name the elephant in the workshop: usually, production flows are fragmented.

Programming is a bottleneck, not because our engineers aren’t skilled, but because they’re overwhelmed by manual nesting, disconnected data, and a production queue scribbled on paper. Machines wait because instructions arrive late. Parts accumulate between stations because no one told the buffer what was coming. Decisions made upstream ripple unpredictably downstream, often colliding with reality at the worst possible moment.

Even our best operators are stuck reacting—never anticipating. And that’s the paradox: in an age of digital transformation, we’re still managing production like it’s 1995. We don’t need more data—we need connected decisions.

The end-to-end shift: a new industrial intelligence

True end-to-end process management is not a software. It’s not a feature. It’s an operating system for the factory.

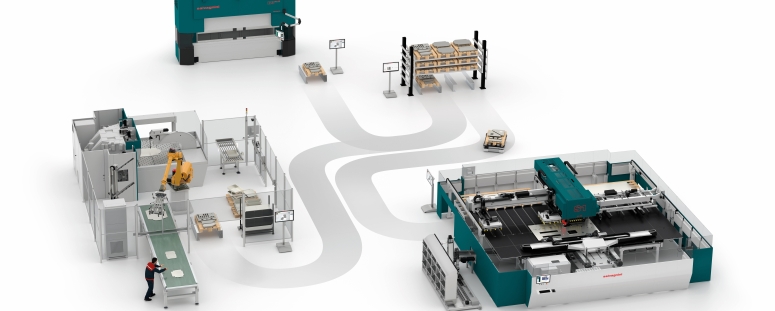

It starts when a production order is generated. In a traditional setting, this is printed, handed off, reinterpreted. In an end-to-end manufacturing ecosystem, it becomes a live object—visible, traceable, and dynamic. It moves from ERP to nesting software, to machine programs, to sorting strategies, and even into the logic of unloading robots. Automatically. Intelligently. Adaptively. Efficiently.

The benefits? They’re not abstract-they’re operational.

Shorter programming times. With a unified architecture, CAD/CAM software can generate optimized programs in minutes, not hours. Operators can fine-tune with simple interfaces, not arcane codes.

Smarter nesting. Scrap is no longer an inevitable evil. Modern systems allow parts to be nested inside the unused areas of other parts-even reusing internal scrap—boosting material utilization and slashing cost per piece.

Adaptive production strategies. Whether you’re producing kits, make-to-order items, or high-volume standards, an end-to-end manufacturing ecosystem lets you choose the right strategy on the fly, balancing buffer size, sequencing, and labor availability.

Real-time control. From the office, planners can simulate the full production flow, test what-if scenarios, and adjust priorities before mistakes are made on the floor. From the frontline, operators can switch modes-straight flow, dynamic buffering, kit reordering-based on the current shift, workload, or part mix.

From automation to autonomy

Good automation is not about eliminating people. It’s about elevating them.

End-to-end process management redefines the role of the operator: not as someone who pushes buttons, but as someone who manages value. With intuitive interfaces, visual programming, and AI-powered tools and simulations, even junior staff can operate complex systems confidently. This reduces onboarding time, minimizes errors, and makes the factory floor more inclusive.

And here’s the hidden power: when repetitive tasks are delegated to machines, human attention is freed for what it does best-judgment, creativity, and problem-solving.

End-to-end is also the answer to the skilled labor shortage. Instead of relying on tribal knowledge locked in a few experts, we build systems that encode that knowledge—systems that can teach, guide, and support anyone willing to learn.

Cost, reimagined

Let’s talk about cost—not in spreadsheets, but in systems thinking.

A machine that operates at 90% capacity is not necessarily “efficient” if it creates bottlenecks downstream. Maximizing machine output in isolation often inflates inventory, delays shipping, and generates chaos in assembly. And this is not just a question of space or logistics-it’s a question of finance. Excessive intermediate storage translates directly into higher inventory carrying costs, longer capital lock-up, and a negative impact on cash flow. Material sitting in a warehouse is capital that’s not working for you.

Optimizing the productivity of one workstation at the expense of the entire flow may boost a single KPI, but it undermines the company’s financial agility. What we need is flow efficiency, not local efficiency.

End-to-end manufacturing ecosystems optimize the whole, not the parts. They create a production logic that aligns takt time, nesting efficiency, workload balance, and part traceability in a single continuum. That means less rework. Fewer surprises. Faster ROI.

It also means resilience: when demand changes, the system adapts-not just in theory, but in execution. That’s real flexibility. And in a market defined by volatility, it’s the only kind that matters.

The invisible benefits

Not all value is visible on the factory floor.

A well-implemented end-to-end strategy affects how you quote, how you plan, how you deliver. With traceability and real-time feedback loops, you can base your costing on actual data, not assumptions. You can promise delivery dates with confidence, not hope. You can reduce the cost of poor quality-not just in rejects, but in reputation.

And perhaps most importantly: you can grow.

End-to-end manufacturing ecosystems are modular and scalable. They allow small improvements today to compound into transformative gains tomorrow. They’re not rigid-they’re alive. And they grow with you.

Toward a system without excuses

The future is not built on machines-it’s built on systems without excuses.

No more “we didn’t know.” No more “we forgot to update.” No more “it wasn’t in the nesting.” With end-to-end approach, everything is known. Everything is visible. Everything is accountable. That’s the shift.

And once you experience it, there’s no going back.

Because it’s not just about producing more. It’s about producing better. With intelligence. With intention. With a system that finally makes sense-not just to the machine, but to everyone in the company.

The factories of the future won’t run faster. They’ll run smarter.

And the smartest ones? They’ve already started.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Optimise your processes Guest columns

Optimise your processes Guest columnsBeyond the bottleneck: rethinking manufacturing with end-to-end process management

Published on 03/09/25