The digital transformation has fundamentally changed industrial manufacturing – including welding technology. Despite initial reluctance, the industry is catching up. The reason for the delay is not a lack of willingness to innovate, but rather the high complexity of the welding process: The electric arc combines numerous physical influencing factors – from material properties and component geometries to environmental conditions. Those who digitally master this complexity are setting new standards in efficiency, quality and process reliability – and are now gaining a decisive competitive advantage.

The digital transformation has fundamentally changed industrial manufacturing – including welding technology. Despite initial reluctance, the industry is catching up. The reason for the delay is not a lack of willingness to innovate, but rather the high complexity of the welding process: The electric arc combines numerous physical influencing factors – from material properties and component geometries to environmental conditions. Those who digitally master this complexity are setting new standards in efficiency, quality and process reliability – and are now gaining a decisive competitive advantage.

Technological drivers and potential

Modern sensor technology, powerful data processing and AI now enable precise recording, analysis and control of welding processes –even for highly varied components and single-unit batches. Digital assistance systems support skilled workers, take over routine tasks such as documentation or deviation analysis, and create space for quality-related decisions. The goal is transparent, reproducible manufacturing with high quality.

From data graveyard to intelligent use

However, data alone does not create added value. Without structured collection, contextualization and systematic evaluation, it risks turning into a data graveyard. Only by linking it to component information, environmental conditions and quality requirements can a foundation be created for well-informed decisions and automated optimization. It is crucial that data is actively fed back into the ongoing manufacturing process – as an integral part of intelligent process control.

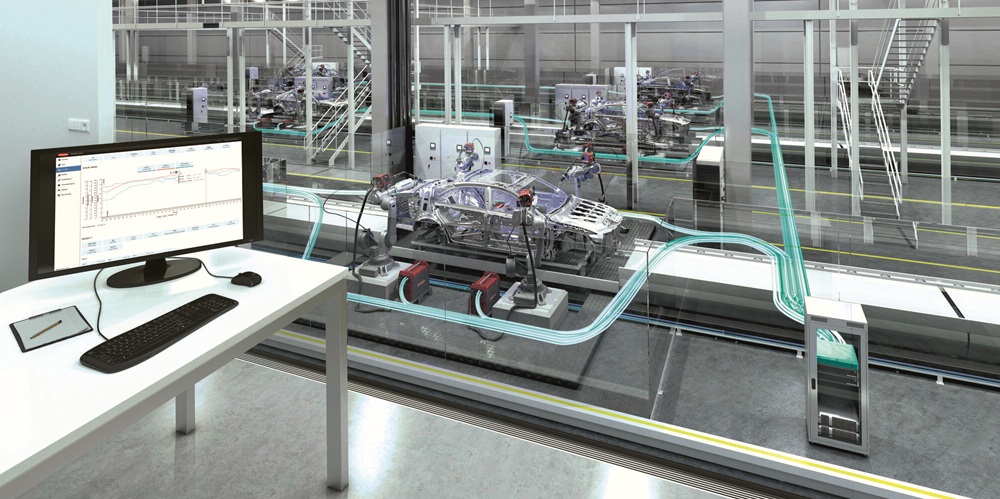

Copyright: Fronius International Concrete applications for digital solutions can be found throughout the entire welding manufacturing process:

- Offline robot programming

- Parameter determination

- Cobots in welding operations

- Guided welding sequence plans

- Integrated workflows for process stabilization

- AI-supported welding fault detection

These solutions not only increase quality, but also reproducibility and efficiency.

Digitization as an individual transformation process

Digitization is not a product – it’s an individual transformation process. For companies, this often means adapting existing IT structures and established working methods. This complexity often causes hesitation or resistance. Manufacturers are therefore required to actively support their customers – with clear, step-by-step concepts that are tailored to each customer’s specific starting point.

Many data-based solutions are not developed in the laboratory, but in real-world production environments. Only there can systems be validated and further developed. This requires trust, cooperation and a willingness to collaborate on development. In order to create scalable solutions, standardized interfaces and close coordination between industry, manufacturers and standardization bodies are also needed.

Conclusion

The digitization of welding technology is not an end in itself, but a key to sustainable competitiveness. Those who use data intelligently create the basis for stable processes, reproducible quality and future-proof manufacturing. The decisive factor here is the gradual joint development and research of new data-based solutions with practical relevance and strategic foresight.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

- Welding technologies Guest columns

Digitization in welding technology: From data graveyard to process intelligence

Published on 29/10/25