Manufacturers that use cutting machines, and more specifically laser cutting tables, consume a lot of gas, particularly nitrogen and oxygen. Managing the logistics of this consumable is sometimes complex because gas requires stock management. As such, manufacturers are forced to:

- constantly monitor the level of gas remaining in their tanks to avoid running out,

- anticipate orders for conditioned or liquefied gas, according to their partner gas supplier’s resupply times and delivery schedule,

- comply with regulations relating to the quantity that can be stored on-site,

- undergo fluctuating gas prices that do not allow good visibility of machine operating costs.

Within this context, how can you move away from the constraints of nitrogen and oxygen supply management? How can you reduce the operating costs of cutting machines by reducing the cost of gas? How can you limit the environmental impact of gas supply?

To answer these questions, Metal-Interface interviewed Laurent Zenou, Managing Director of NOVAIR, a company specialising in the production of gas directly on-site, at users’ factories.

Overview of Industrial Gas Production and Supply Channels

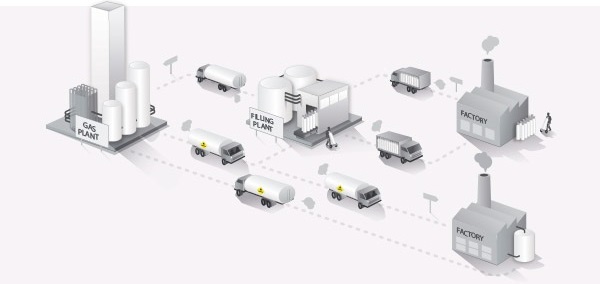

Rotation between gas plants and users - Copyright Novair

Most manufacturers work with centralised industrial gas production sites. The gas is then conditioned or liquefied and delivered to the end-user’s site, such as a sheet metal subcontractor or manufacturer that uses laser cutting, oxy-fuel cutting or plasma machines, etc.

On-site gas production - Copyright Novair

For manufacturers with a very high gas consumption, such as steel mills, large suppliers can install production plants directly on-site, where the gas is used. Indeed, delivery by truck would not ensure sufficient supply.Finally, oxygen and/or nitrogen generators can also be installed directly on-site, close to a laser cutting machine, for example. The aim is to continuously produce the gas required for one or more cutting machines, using ambient air.

This type on on-site production solution has already been used for several years to supply health facilities with medical oxygen.

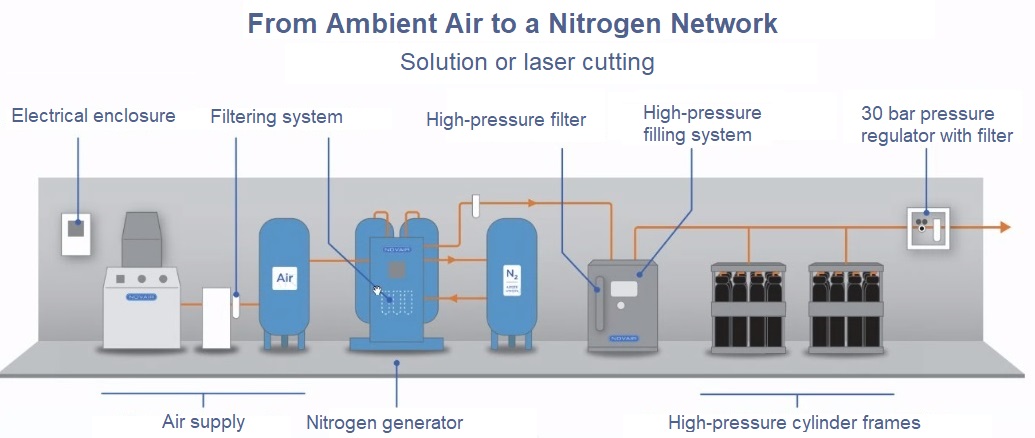

Diagram of a nitrogen or oxygen generator for powering laser cutting machines - Copyright Novair

Over the past few years, this type of installation has been adapted to meet industrial gas needs for companies of all sizes. The generator is sized according to the company’s gas needs and has a back-up system in case of a main generator failure, to avoid any supply interruptions. This new way of meeting industrial gas needs is not widely known to sheet metal subcontractors and manufacturers using laser, plasma, or oxy-fuel cutting machines, among others.

On-Site Gas Production: No More Logistical and Management Constraints

Manufacturers can gain in autonomy by producing gas directly on-site, where their machines are used. This enables companies to break free of gas management constraints: no more checking tanks for gas levels, supply management, delivery problems, risk of production stoppage due to a lack of gas, etc.Laurent Zenou adds that, "each manufacturer will become autonomous and will produce its own gas continuously, without supply or logistical constraints, in complete autonomy.”

Nitrogen and Oxygen: Reducing the Bill by 20 to 50%?

For companies that perform laser cutting, purchasing gas is an expense item that significantly impacts the cost of operating equipment and its profitability.

Prices on the industrial gas market are volatile and may vary depending on the distance between the manufacturer’s site and the gas supplier’s logistics centre, competition between gas suppliers in the region, etc. Furthermore, the cost of gas also depends on the quantity used, which fluctuates from one month to the next according to variations in the company’s activity. It is therefore difficult for companies to manage their budget for this expense item.

Copyright Novair When a nitrogen generator is installed, it is sized with the manufacturer according to their needs in terms of capacity. A system for filling nitrogen cylinders on-site to store extra also helps absorb consumption peaks.

Laurent Zenou adds: "Companies know the exact cost of the nitrogen/oxygen supply for their machines. Depending on the company’s situation, they can reduce their gas budget by 20 to 50%.”

Land and Regulatory Limits

There are also land constraints involved in the traditional supply of gas. Indeed, the tanks must be at ground level, in an area that can be accessed by truck, with enough space to turn around.

An on-site gas production generator allows to break away from these constraints, because they can be installed indoors, outdoors, on the roof, in the basement, or elsewhere.

Installation of a generator in a small space - Copyright Novair Laurent Zenou gives an example: "This solution can sometimes solve certain manufacturer problems. For example, we worked with a manufacturer that could not expand because the only place they could store their nitrogen and oxygen prevented them from extending their factory. The solution was to install a gas generator on the roof, as close as possible to their laser cutting machine.”

For oxygen users, the quantity of gas you can store is highly regulated. Laurent Zenou adds: "This is a real problem for manufacturers who are subject to declarations such as the French ICPE, in terms of the classification of installations. A company that consumes a lot of oxygen is therefore subject to significant regulatory constraints.”

With an oxygen generator, production is carried out on-site and the quantity of gas stored at any given moment should be extremely low, and below the thresholds requiring the classification of installations and ICPE declaration.Gas Quality and Traceability Management

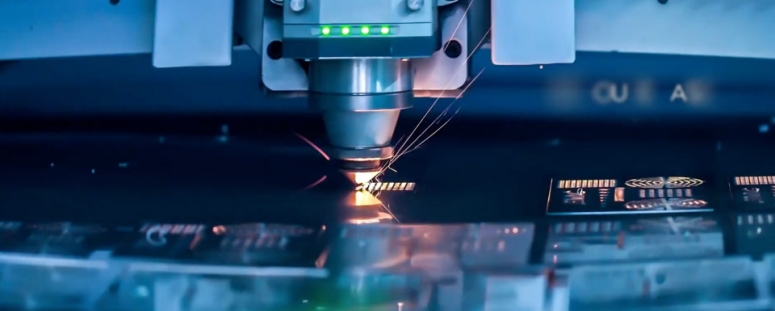

Cutting quality - Copyright Novair Some manufacturers or sub-contractors need to manage the quantity of gas used, as well as its traceability. Laurent Zenou adds that, "in certain industries, such as aeronautics, traceability is required throughout the manufacturing process. It is sometimes a key element."

Generators produce up to 99.999% pure nitrogen (10ppm residual O2) and are equipped with a system to continuously monitor the quality of gas produced and its purity. If the gas produced does not match the required levels, the generators are equipped with an automatic cut-off system, so as to not pollute the network, products or process.

On-Site Production… an Environmental Approach

From an environmental standpoint, producing gas on-site is optimal, because the gas no longer needs to be transported from one place to another. As Laurent Zenou says, "there are no CO2 emissions because there are no trucks on the road to transport the gas".

Producing gas directly on-site, where it will be used, is a departure from industrial consumer habits. By using this proven technology, manufacturers can secure their gas supply and play a role in eco-responsible consumption.

Copyright - Reproduction prohibited without the written permission of Metal-Interface

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

Gas Technical article

Gas Technical articleNitrogen and Oxygen for Laser Cutting: How to Produce it On-Site