Even in this age of automation and cobots, manual welding remains an indispensable part of the metalworking industry. The reasons are obvious: no other process offers this much flexibility—whether in small workshops, on construction sites, or in industrial shift operations. At the same time, requirements are increasing: every seam must be perfect, standards and documentation requirements are growing, and the shortage of skilled workers is further exacerbating the situation.

Even in this age of automation and cobots, manual welding remains an indispensable part of the metalworking industry. The reasons are obvious: no other process offers this much flexibility—whether in small workshops, on construction sites, or in industrial shift operations. At the same time, requirements are increasing: every seam must be perfect, standards and documentation requirements are growing, and the shortage of skilled workers is further exacerbating the situation.

What does this mean for the future of manual welding?

1. Ease of use and intelligent assistance

I see four important areas: Many welding professionals want machines that are easy to use - according to the motto "less is more". At the same time, there are specialists who value maximum variety and individual freedom. The solution lies in systems that can do both: intuitive operation for newcomers and advanced functions and individual setting options for professionals. Predefined characteristic curves and welding parameter wizards help to make the optimal selection, avoid errors, and ensure quality-even if experience is (still) lacking.

Many welding professionals want machines that are easy to use - according to the motto "less is more". At the same time, there are specialists who value maximum variety and individual freedom. The solution lies in systems that can do both: intuitive operation for newcomers and advanced functions and individual setting options for professionals. Predefined characteristic curves and welding parameter wizards help to make the optimal selection, avoid errors, and ensure quality-even if experience is (still) lacking.

2. Flexibility and futureproofing

Business requirements are changing rapidly. Modern systems must be robust, durable, and modularly expandable in order to grow with requirements. Sophisticated multi-process welding systems are becoming increasingly important because they allow companies to perform a variety of tasks with a single machine – from TIG and MIG/MAG to manual metal arc welding.

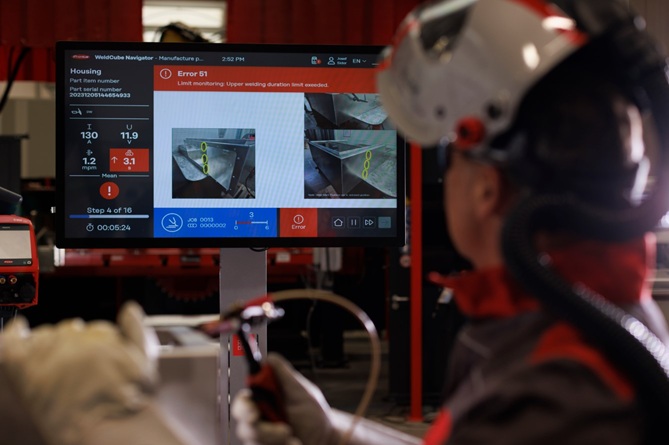

3. Digital support and quality assurance Digitalization has long since arrived in manual welding. It facilitates documentation, enables welding data analysis and the resulting improvements, and supports the training of new employees. Functions such as digital WPS documents, secure access authorizations, and step-by-step instructions thanks to weld sequencing ensure quality and efficiency. This also makes knowledge directly available in the machine, a decisive advantage in times of skilled labor shortages.

Digitalization has long since arrived in manual welding. It facilitates documentation, enables welding data analysis and the resulting improvements, and supports the training of new employees. Functions such as digital WPS documents, secure access authorizations, and step-by-step instructions thanks to weld sequencing ensure quality and efficiency. This also makes knowledge directly available in the machine, a decisive advantage in times of skilled labor shortages.Thanks to AI/AR support, learning to weld is now a modern, safe, and resource-efficient experience. Much of the manual skill is learned at a high level in virtual space and then perfected in practice.

4. Health protection – safety for all the senses

Welding is a profession that challenges all the senses: heat, light, smoke, and noise accompany every step of the process. This makes it even more important to provide welders with comprehensive protection—not only from obvious hazards such as flash burns or burns, but also from fine dust and smoke particles.

Modern personal protective equipment goes far beyond the classic helmet: smart welding helmets with automatic darkening and Bluetooth connectivity adapt to the welding system in real time. Fresh air helmets with integrated blower filter units ensure clean breathing air, while extraction welding torches and mobile extraction systems eliminate a maximum of pollutants directly during the welding process – as studies in collaboration with leading institutes have proven. Ergonomics in welding is also a key issue. Specially designed welding torches or ball joints on hose packages can reduce the strain on welders. All these solutions show that health protection is now at the highest technical level and plays a decisive role in keeping welders healthy and productive.

And the technology?

Innovations such as adaptive wire feed in TIG welding or mechanical assistance systems for MIG/MAG show how precision and speed can be increased while reducing the strain on welders.

Innovations such as adaptive wire feed in TIG welding or mechanical assistance systems for MIG/MAG show how precision and speed can be increased while reducing the strain on welders.For example, a new assistant for MIG/MAG welding guides the specialist-similar to a lane departure warning system-with additional wire, constant speed, and consistent distance along the seam edge.

With such assistants, perfect TIG visible seams or precise long MIG/MAG seams, complex geometries, and constrained positions become much easier to manage.

Conclusion

Manual welding is evolving—not as a competitor to automation, but as a complement to it. With intelligent, versatile, and digital solutions, it will remain a key process for quality and cost-effectiveness in the future. Comprehensive health protection is equally important: modern technologies and ergonomic solutions ensure that welding specialists not only work efficiently, but also safely and healthily. It is crucial that technology supports people-not the other way around.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

- Welding technologies Guest columns

Manual welding reimagined: flexible, digital, safe

Published on 15/01/26