Production optimization and digitization

Specializing in the automatic nesting of complex shapes for cutting since its creation in 1979, Alma designs innovative software solutions to optimize the material consumption and potential of machines and robots. Alma has always supported the development of emerging technologies, and works closely with manufacturers of machine tools and robotic systems. Alma is constantly striving for innovation, and invests over 25% of its sales in R&D every year.

A thriving international group

Alma's software products are marketed through an extensive distribution network comprising subsidiaries (Italy, Germany, China, Brazil, USA, Singapore), dedicated resellers, integrators and partners worldwide. Alma is an independent, solid and forward-looking group.

Values focused on people and customers

Incorporated as a cooperative society (Scop) since its creation in 1979, Alma in France is 100% employee-owned. This cooperative status has left its mark on Alma's culture and values: shared decision-making and results, solidarity, a spirit of responsibility, special attention to the quality of customer relations, and so on. Backed by its cooperative and human values, Alma pursues an industrial strategy based on the long-term viability of its corporate project, the involvement of its employees and a lasting partnership with its customers.

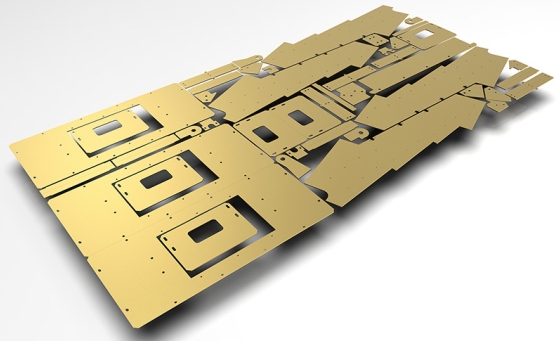

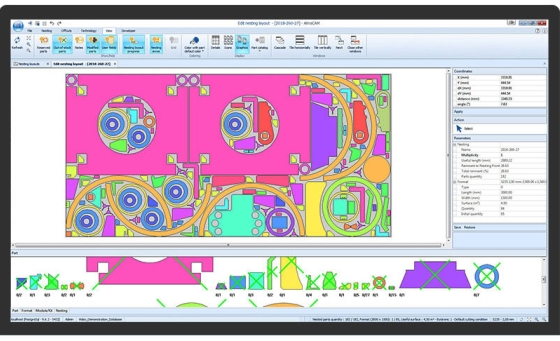

Nesting

With unrivalled expertise in cutting optimization, Alma provides manufacturers and software vendors with nesting solutions for all technologies and materials.

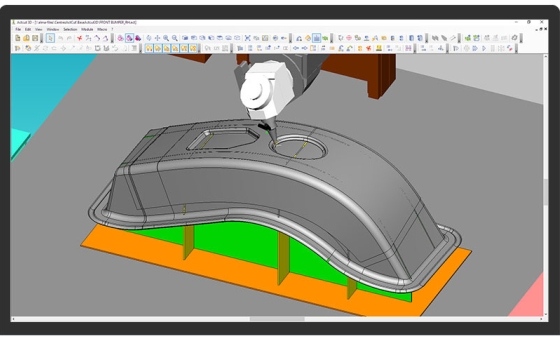

Sheet metal cutting

Fluid-jet cutting, punching, routing... Programming sheet metal cutting machines is at the heart of Alma's CAD/CAM software expertise.

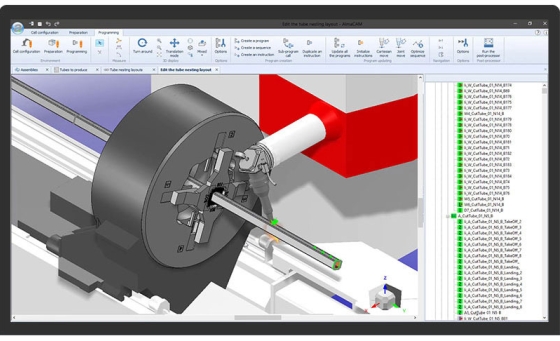

3D/Tube cutting

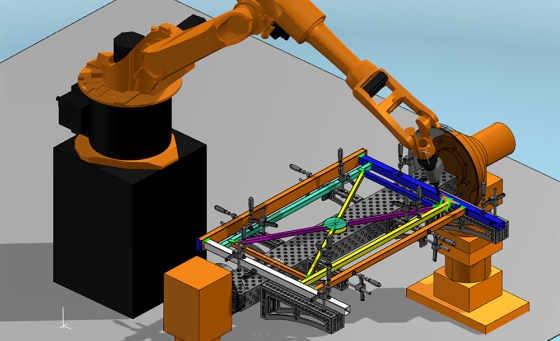

5-axis cutting, tube and profile cutting, robotized cutting: Alma's software programs software controls all 3D cutting machines and cutting robots, with no limit to the number of axes.

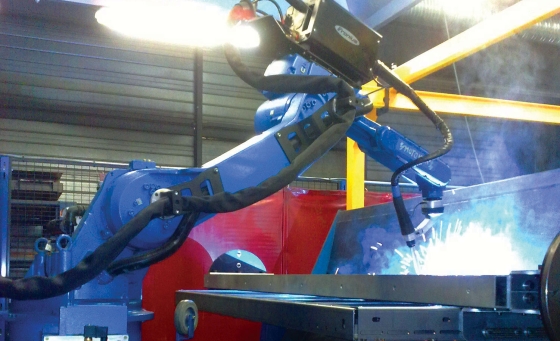

Robotic welding

Forerunners in robotic CAD/CAM 25 years ago, Alma has accumulated unrivalled experience in the development of off-line programming software for welding robots.

Industry 4.0

Digitization of production, automation of sheet metal processes, integration of CAM with the information system, robotics... The Almacam software suite meets the challenges of Industry 4.0.

Cloud

Alma is resolutely committed to the Cloud with its optimization software components for software publishers and its Nest&Cut web application for cutting manufacturers worldwide.

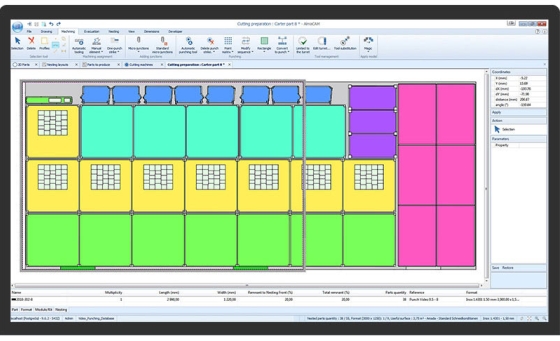

A solution for all 2D and 3D cutting processes

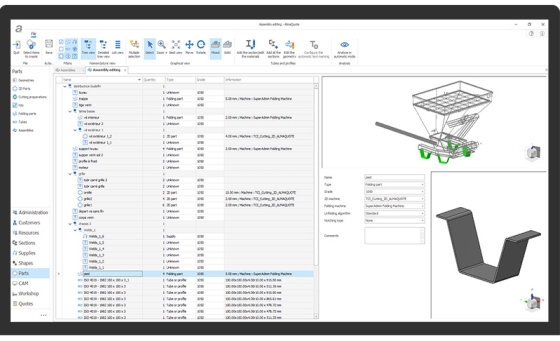

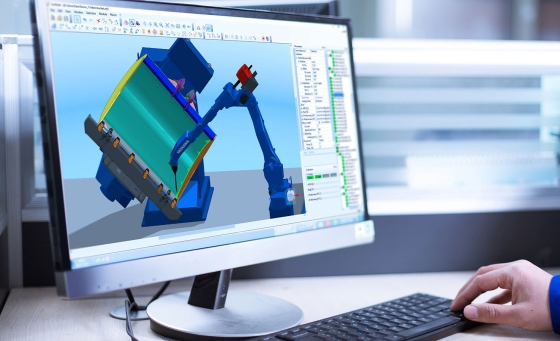

With Almacam, Alma offers a complete range of CAD/CAM software applications for programming flat material cutting machines (laser, plasma, waterjet, oxycutting, punching-nibbling, routing, combined technologies) and three-dimensional cutting machines or robots (5-axis cutting, tube and profile cutting, etc.). From CAD data processing to ISO code generation, Almacam software drives all types and makes of machine, and integrates the specific features of each cutting technology.

Productivity and usability

Almacam is an environment designed to facilitate automated programming and guide the user through the programming process to avoid any risk of error. The system provides automatic assistance at all stages of programming, with the option of fully automatic operation. This ensures a short learning curve and maximum usability.

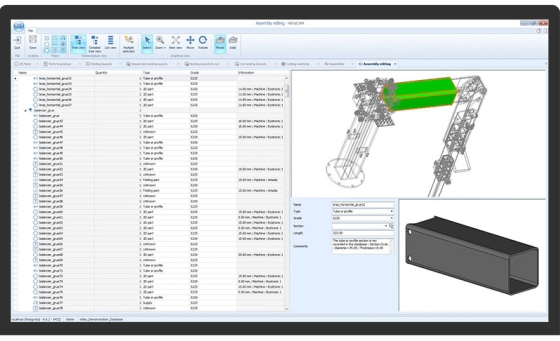

Modules for every job

Numerous CAD/CAM modules are integrated into Almacam: unfolding of sheet metal parts, import and processing of 3D CAD assemblies, developed shapes for boilermaking, cutting of letters and drawings, etc.

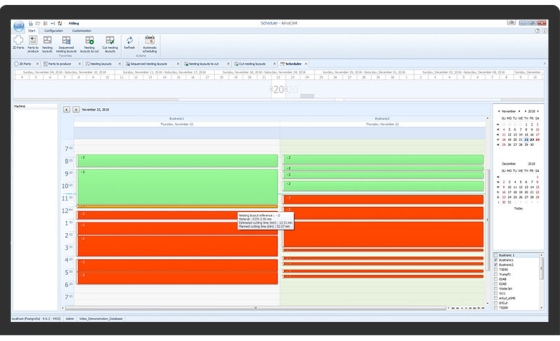

A platform designed for the Smart Factory

Almacam is a set of complementary software applications integrated within a single ecosystem, with secure data management for complete traceability. As an open system, Almacam can be connected to any information system (CAD, ERP, CAM, MES, etc.) and enables complete integration into the digital chain, with production and workshop management tools (quote calculation, management of inventory and manufacturing orders, workshop and scheduling station, etc.)

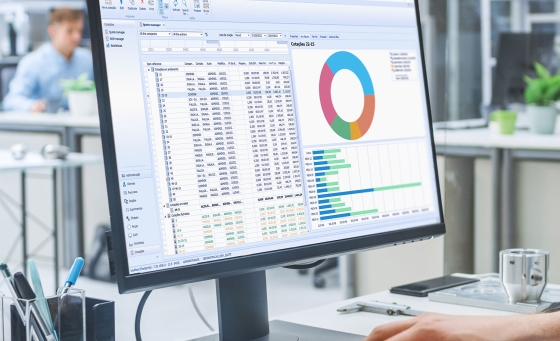

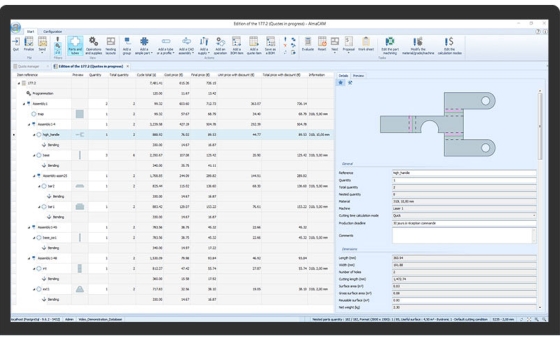

Fast and accurate sheet metal quoting

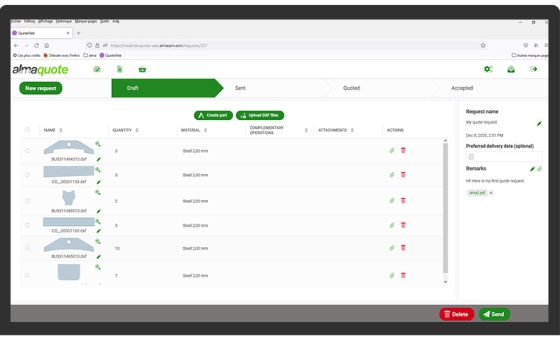

Almacam's integrated Almaquote module enables you to create quotations from the simplest to the most elaborate via an intuitive graphic interface. It is aimed at sheet metal subcontractors who need to respond very quickly to requests for quotations, and at manufacturers who may be looking for customized functions, or even a tailor-made application. With Almaquote, Alma also offers Webquote, a web service that automates the preparation and processing of quotations and facilitates exchanges between subcontractors and ordering parties. With Webquote, users can import and unfold 3D sheet metal parts, and instantly calculate the cost of cutting and bending operations, enabling them to automatically obtain reliable quotes online.

A pioneering solution

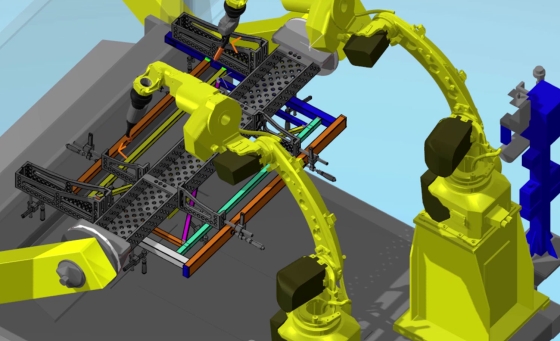

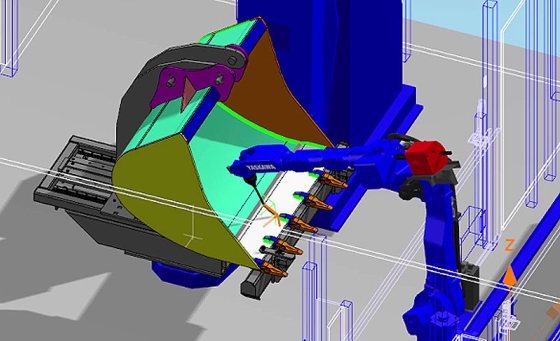

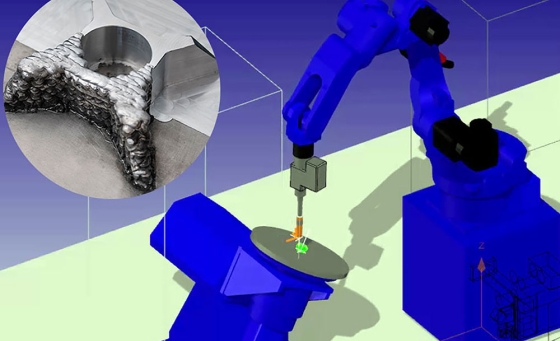

Since the launch in 1996 of its software developed in collaboration with the French Institut de Soudure (Welding Institute) for a major manufacturer of construction equipment, Alma has constantly improved its off-line robot programming solutions, specialized in arc welding (assembly and additive manufacturing by depositing weld beads) and robotized cutting.

Robotic welding

Dedicated to the off-line programming of arc-welding robots for the assembly of mechanically-welded parts, Almacam Weld enables robots to be programmed faster and at lower cost, to anticipate production and even to validate the design of tooling. With Almacam Weld, programming is simple, automated and optimized for all robot configurations. Thanks to its responsiveness and flexibility, Almacam Weld is ideally suited to short production runs.

Additive manufacturing

Almacam WAAM is an innovative CAD/CAM solution dedicated to robotized DED-WAAM additive manufacturing processes, enabling 3D parts to be produced by successive from any type of weldable material. This technology opens up promising prospects in industry. Almacam WAAM manages the entire robot programming process, and the finishing of the part by material removal can then be programmed in CAM Machining.

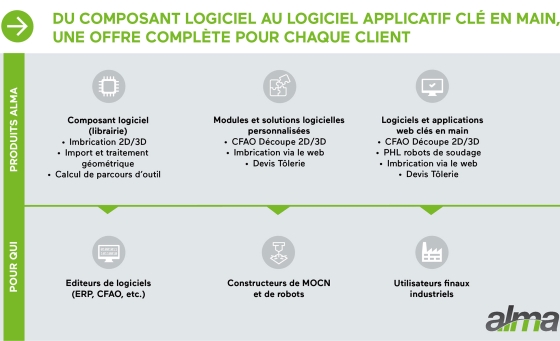

A solution for every customer profile

Alma's modular, scalable offering enables us to meet the needs of all our customers:

- Application solutions for industrial end-users with Almacam, a complete range of CAD/CAM software for all technological processes in sheet-metal working and mechanical welding.

- Software components, in particular nesting algorithms, for integration into applications developed by third parties: CAD/CAM or ERP software developers, manufacturers who publish their own software, etc.

- Web services enabling end-users to run Alma software in SaaS mode without investing in a costly solution, while providing access to a hybrid "fat client/web" Alma offering.

Tailor-made partnerships with machine-tools builders

Whether for cutting or robotized applications, Alma's software can be customized for specific technologies or uses, well beyond the post-processor. This makes them particularly easy for machine tool builders and integrators to integrate. Combined with the technical performance of Alma's software, this advantage gives the builder's solution decisive added value. Alma adapts to the needs and constraints of the builder, offering a broad portfolio of services worldwide.