Professionalism and Evolution

- Founded in 1969, BI-ME is a leader in the field of precision mechanics, in particular in the construction of sheet metal moulds and spare parts according to drawing, thanks to over 50 years of experience, handed down from the founding members to the new generations. The company's path reflects professionalism, entrepreneurial skills and continuous evolution.

Commitment to quality

- The quality of BI-ME products testifies to its commitment, with particular attention to the use of specialized personnel, rigorous processing controls and the use of highest technology machinery.

Adapting to market dynamics

- BI-ME's success over the decades is attributed to its strong market awareness, investment in training and technology, moreover it take care all customer requests and regard delivery time accorded.

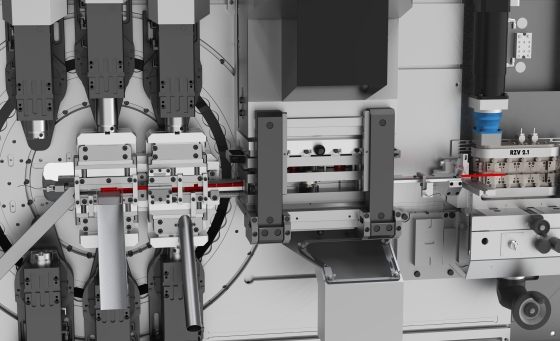

Sheet metal moulds

- Sheet metal moulds are at the heart of BI-ME's production, accompanied by detailed construction drawings for the precise execution and reproduction of spare parts.

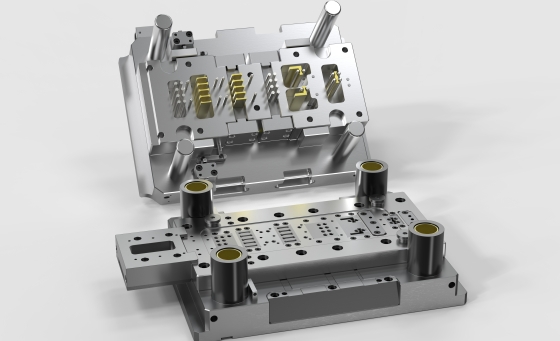

Production of high-precision parts

- BI-ME also excels in the production of high-precision steel and carbide parts, in small series too, meeting all technical, quality and precision demand required by the customer.

Mould maintenance and after-sales service

- The company not only manufactures molds but also provides after-sales service.

- We absolutely avoid to leave our customers alone and we use lots of our resource for support him on any next phases.

- For example we give an active support and help to get maximum otimization on the production lines in direct collaboraion with the production chiefs.

Advanced use of materials

- BI-ME products are made of sintered steel and the best on market carbides, accurately choice for the right applications, ensuring high durability and top quality.

In-house design capabilities

- The company is able to develop designs completely autonomously, and delivery them in 2D and 3D CAD format, meeting a wide range of design needs and complexities. In recent years, thanks to the collaboration with PENTAP srl, we have been able to expand our offer in terms of quality and quantity, managing to satisfy even the most complex requests that are submitted to us daily.

Customized production cycles

- Supported form a real advanced internal management system, we develop customized production cycles for each specific detail to be produced, with the aim of making the production phases faster and more effective. In addition, we are able to plan all of our production, thus being able to meet the increasingly tight deadlines that the current market requires.

ISO 9001:2015 Certification

- BI-ME's organization has been ISO 9001:2015 certified since 2018, which underscores its dedication to quality management and customers satisfaction.

Consistent, high-quality service

- With over 50 years of experience and a well-equipped machine park, BI-ME guarantees consistent, high-quality services tailored to the customer's needs.

Speed and accuracy

- Speed and precision are constant in BI-ME's production process, ensuring to be ever on time and a precise alignment to all customer requests.

Ongoing support and solutions

- The company's support team is always ready to provide solutions and support, demonstrating an exceptional commitment to its customers.

BI-ME's mindset in precision mechanics since 1969 is built on a foundation of technical expertise, customer-oriented services, and a commitment to continuous improvement and innovation.