Identity and approach

Spaleck Industries is a major player in the finishing equipment sector, playing a triple role as designer, manufacturer and integrator. The company aims for a global approach, presenting itself as an essential partner for each customer's specific finishing challenges. This global approach takes into account crucial aspects such as workplace safety, energy savings, environmental impact, cost and profitability, while ensuring quality and reliability. In short, the company adopts an approach that respects both the environment and people.

Missions and values

Providing optimal solutions is at the heart of Spaleck's concerns. By actively listening to its customers, the company is dedicated to offering innovative solutions, while promoting French know-how that respects environmental standards. Beyond the quality of its products, Spaleck insists on the importance of teamwork and passion for what we do, while emphasizing high standards at all levels of the company.

Innovation strategy

Focused on innovation and quality, Spaleck's strategy is based on five main axes. Among these, the company aims to secure and anticipate the future of connected machines, standardize while offering adaptability, and strengthen its international footprint. In addition, it is committed to demonstrating its expertise through the establishment of a test center, while systematically prioritizing environmentally-friendly solutions.

SPK AERO machines

Mainly suitable for parts up to 6200 mm, this model is ideally suited to profiles, stiffeners and seat rails. Its design allows simultaneous processing of several parts directly after machining, without any risk of alteration.

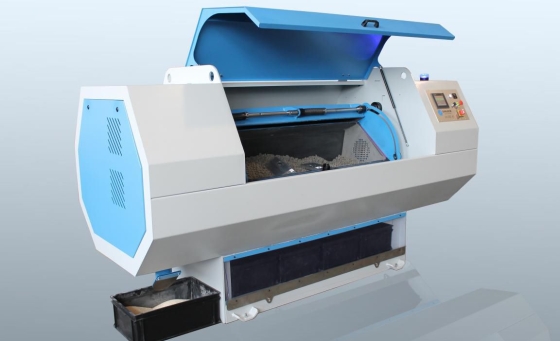

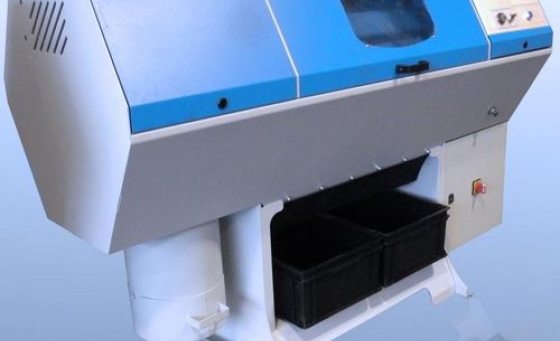

XA deburring barrel

This machine is designed for parts up to 1350 mm. Its ability to handle a wide range of parts gives it a distinct advantage in subcontracting markets, underscoring the importance of its versatility.

Deburring barrel A

Dedicated to parts up to 650 mm, this barrel is distinguished by its ease of use and compactness. It is also equipped with a 230 V connection and a vacuum system, confirming its status as an efficient production tool.

FLADDER deburring machine

This machine is ideal for precision sheet metal work, designed for deburring and corner breaking. Its flexibility also enables optimum finishing of volumetric parts.

Deburring barrel Y

Ideal for parts up to 1380 mm and weighing 30 kg, this model is designed for high production rates. Modular as required, it also offers loading and unloading options for easy handling.

PX deburring

Designed for parts up to 1350 mm, it can handle a wide range of workpieces. In addition to deburring, it can radius and descale small parts, and even guardrails.

Deburring DIABOLO

Similar to the "A" model, this barrel is dedicated to parts up to 650 mm. It features a 220 V connection and combines simplicity of use with compactness, confirming its role as a production tool.

MDL deburring

This barrel, suitable for parts up to 1250 mm, offers a good balance between capacity, cost and robustness. It also features a suction and cleaning system, with an ergonomic door opening for the user.

EBOX deburring machine

Specifically designed for flat deburring of surface parts, this machine uses a metal brushing system with carrousel. It is designed for workshops producing primary parts, with a processing width of up to 2,500 mm.

Aeronautical sector

SPALECK Industries has developed a range of finishing machines specifically for the aerospace industry. This equipment is designed to process aerostructure components, whether volumetric or surface, in various alloys obtained by high-speed or dimensional machining. This technique meets the requirements of aerospace giants such as AIRBUS and BOMBARDIER.

Metallurgy and mechanics

The "AEROFINITION" range from SPALECK Industries is designed primarily for the metalworking and mechanical engineering industries. This range covers a wide spectrum of activities, from precision machining and industrial sheet metal work to metalwork. Thanks to their deburring machines of varying capacities, they can meet the varied needs of these sectors.

Custom engineering and design

SPALECK Industries' "FINITIONINNOVATION" department offers expertise in technical and financial engineering. Responding to specific needs, this branch takes charge of the design of special machines, supplying complete finishing solutions or equipment designed to improve part of the production process.

Extending solutions

With "INNOVATIONEQUIPEMENTS", SPALECK Industries expands its range of machines, offering a wider range of solutions to meet the diverse needs of its customers.

Services and support

SPALECK Industries doesn't just supply equipment; the "EQUIPEMENTSSERVICES" department is dedicated to supplying consumables, spare parts and carrying out interventions. With a view to providing a comprehensive service, they wish to offer a complete service via SPK SERVICES to guarantee customer satisfaction.