For more than thirty years, over time and by dint of engineering, Spaleck Industries has imagined deburring processes (patented) offering numerous advantages on the environmental, ergonomic and economic levels.

A patented deburring process adapted to needs of customers

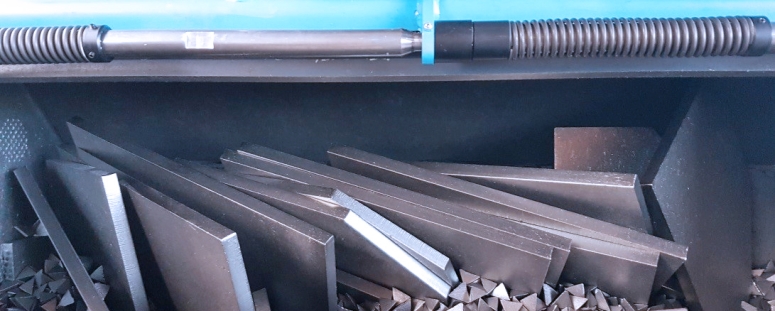

Today, its range of SPK deburring barrels is based, among other things, on the SPIC® process, ecological and patented, which makes it possible to deburr and degrease parts of different materials in a soundproof rotating tank in accordance with the requirements clients.

To avoid the production of effluents, SPALECK INDUSTRIES is part of "clean" production and develops eco-responsible dry finishing treatment solutions without the use of chemicals or the discharge of sludge and wastewater.

The SPK Solutions brand offers a very wide range of deburring machines and specific automated lines, but also a range of standard machines to meet the needs of diversified activities and facilitate the handling of parts.

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

EuroBLECH 2022 Press release

EuroBLECH 2022 Press releaseSPALECK INDUSTRIES - THE SOLUTION FOR DRY DEBURRING

Published on 09/09/22