ZOOMFAB (ART PETRUS SARL) is a manufacturing management software and monitoring hardware company based in the Principality of Monaco, founded in 2014. Its products are aimed at the sheet metal fabrication and machining industries.

ZOOMFAB Manufacturing supervisory system (MSS) is an Industry 4.0 application that includes:

- autonomous machine monitoring

- automated extended machine data collection (EDC)

- ERP and shopfloor two-way production data exchange

- comprehensive productivity management

- "What if?®" modelling and simulation

- machine and work centre financial performance

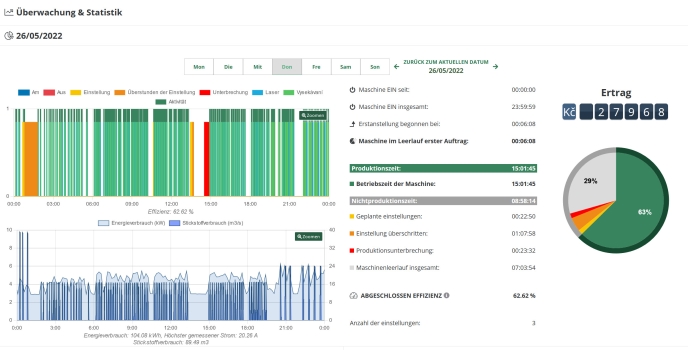

- energy consumption monitoring

- asset management

- scheduled maintenance and calibration management

- automated critical data reporting

ZOOMFAB Manufacturing supervisory system (MSS) is offered as a Software as a Service (SaaS) and includes machine monitoring hardware.

ZOOMFAB gives you better control, additional capacity, shorter lead-time and more profit

ZOOMFAB® Industry 4.0 IIoT platform with software and hardware integration

ZOOMFAB is a cloud-based software application (SaaS) that uses non-invasive battery-powered wireless IIoT sensors to collect data directly from the machines. As no internal IT infrastructure is required, deployment is fast, safe and economical.

ZOOMFAB takes on effective production management and productivity improvement roles not available by most ERP systems. When compared to MES, ZOOMFAB MSS excels with practicality, cost effectivness, speed and easy of implementation, which would benefit the majority of sheet metal and machining job shops, with or without existing ERP. ZOOMFAB's Core function include:

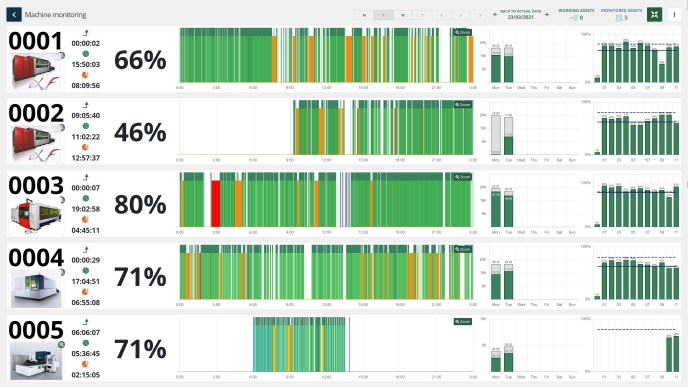

PRODUCTION MONITORING - Machine status and shop floor activities are recorded and displayed in real-time

- Automatic machine monitoring

- Production data collection

- Real-time dashboard, alert and notifications

- Real-time shop floor visibility

STATISTIC AND ANALYTICS - The big picture is at the user's fingertips

- OEE / TEEP

- Trends

- Spare capacity

- Machine downtime and causes

- Energy consumption and cost

FINANCIAL PERFORMANCE - The impact of productivity in financial terms

- Workcentre revenue and profit

- Budgeted vs actual hourly rate

- Machine revenue, profit, ROI and PBP

PRODUCTIVITY MANAGEMENT - Offering much more than numbers and pretty graphs

- Production performance overview

- Automatic reporting of critical data

- Downtime reduction, pro-active management

- Continuous improvement

- Improved communication

- Energy use reduction

BUSINESS STRATEGY - Evaluating past and present, planning for the future

- Hourly rates reserve and competitiveness

- Modelling and simulation

- Investment timing

Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

EuroBLECH 2022 Press release

EuroBLECH 2022 Press releaseZOOMFAB® Manufacturing supervisory system (MSS) for sheet metal fabricators

Published on 10/09/22